Home > Welded Pipes

Welded Pipes form the backbone of global infrastructure — from refineries and petrochemical complexes to long-distance water pipelines, power plants, structural frameworks, and utility networks. A welded pipe is manufactured by forming steel plates or coils into a cylindrical shape and welding the seam, creating a robust, dimensionally stable pipe suitable for medium to high-pressure services.

Unlike seamless pipes, which are produced from pierced billets, welded pipes offer greater diameter flexibility, superior uniformity, and significantly lower production cost, making them ideal for commercial and industrial engineering applications.

Engineers choose welded pipes when diameter range, material availability, and fabrication speed matter as much as performance. Welded pipes also allow:

This is why welded pipes remain the preferred choice for process piping, oil & gas transmission, high-temperature steam lines, structural supports, and city-wide water distribution systems.

The manufacturing process differs by welding technology, each optimized for a specific industrial requirement.

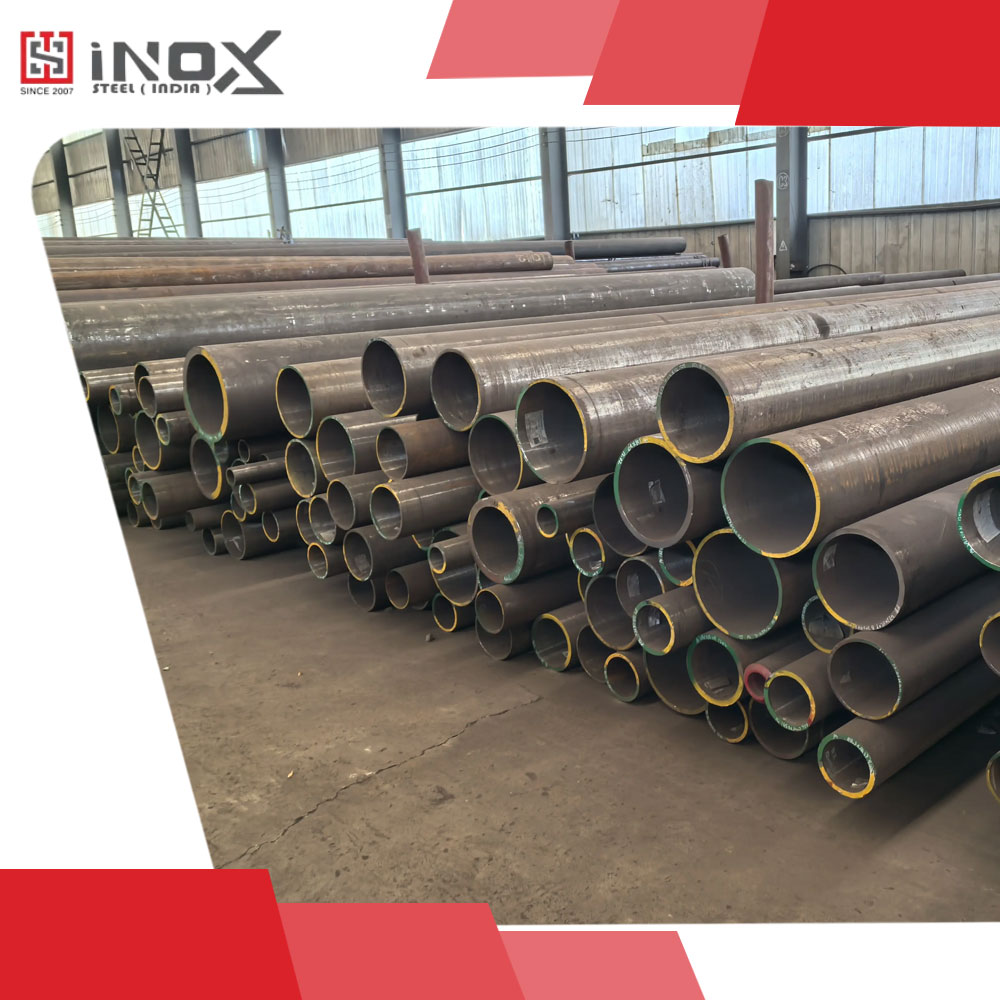

Manufactured from steel coils that are rolled and welded using resistance heat, producing a uniform longitudinal weld without filler metal.

Engineers prefer ERW because:

Common standards: ASTM A53, IS 1239, IS 3589

Used primarily for stainless steel and alloy steel pipes, EFW pipes are welded using high-voltage electric fusion.

Benefits:

Standards: ASTM A312, A358, A409

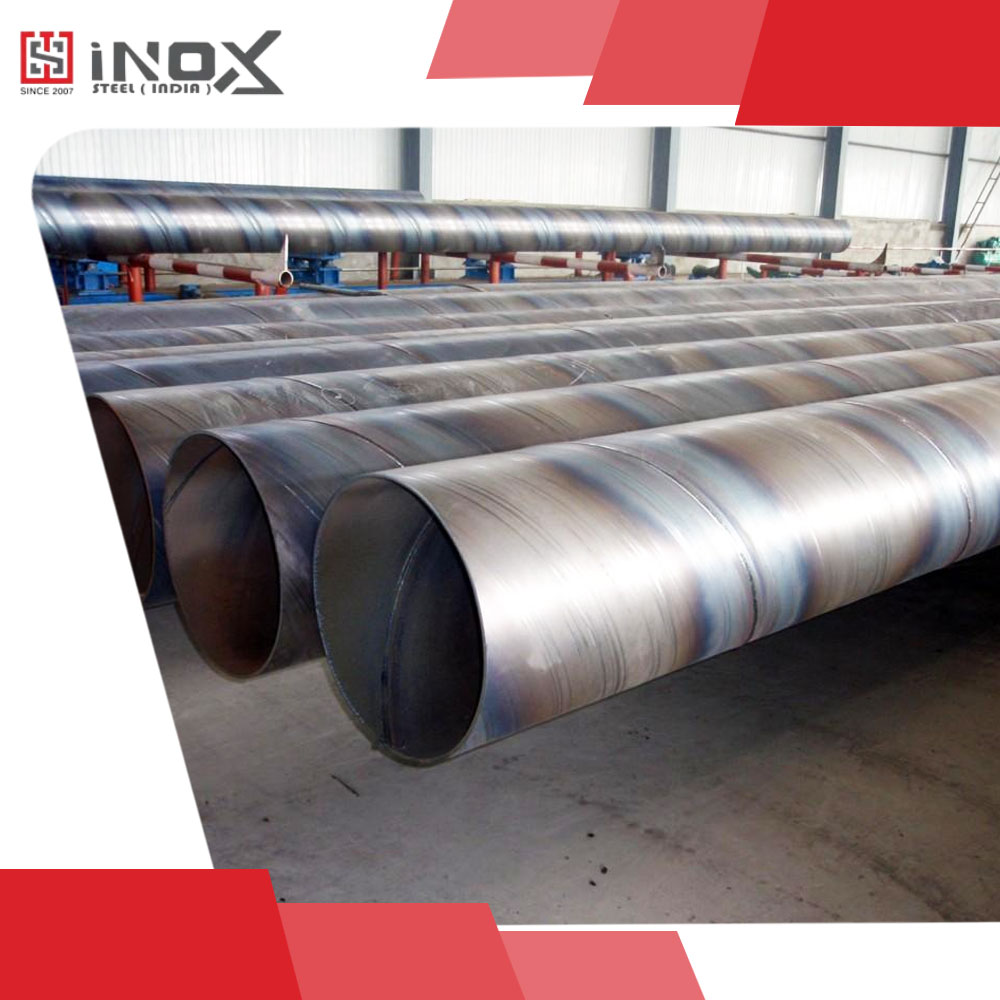

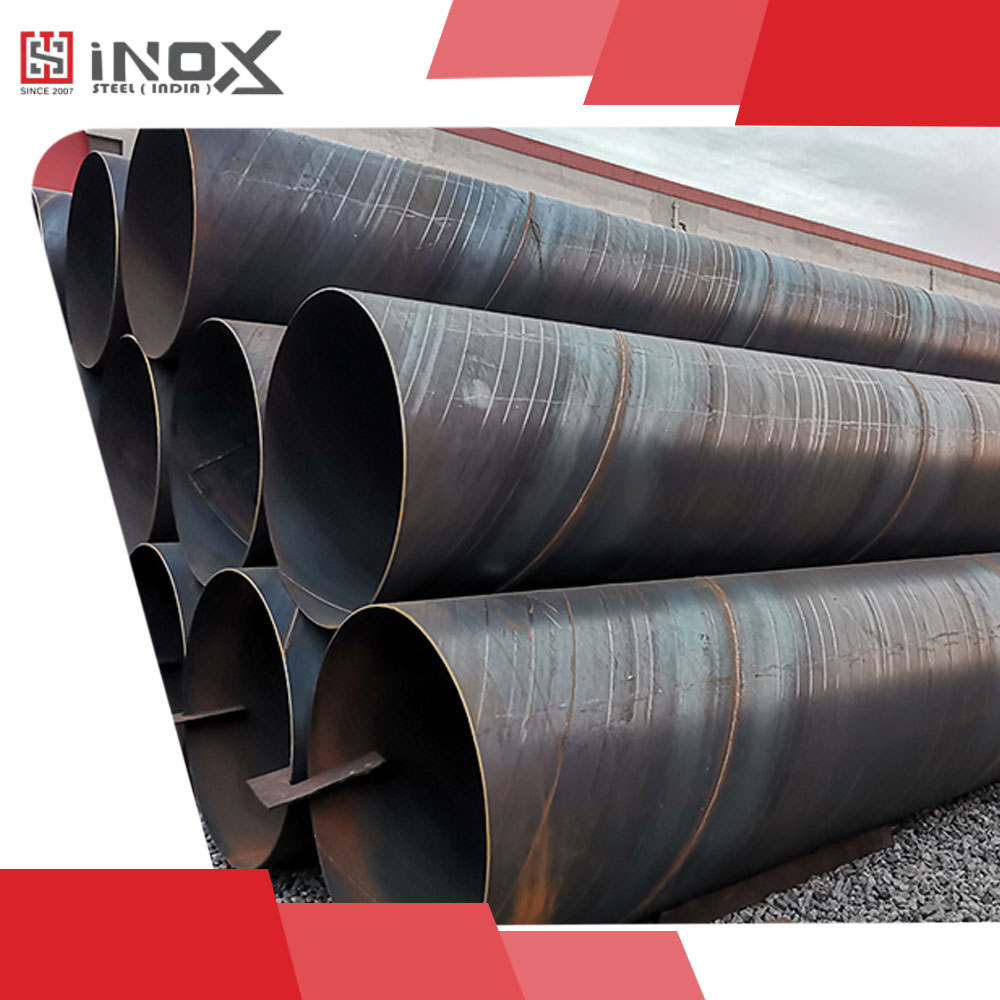

These pipes are produced using submerged arc welding, either longitudinally (LSAW) or spirally (HSAW). They handle extremely high pressures and large diameters.

Advantages:

Standards: ASTM A671, A672, A691, API 5L

Manufactured by spirally forming steel plates. Ideal for long-distance pipelines due to their strength and flexibility.

Custom-made for non-standard diameters and specialized industrial needs, often used in heavy fabrication industries and plant design.

With over a decade of experience and multi-material capability — from Stainless Steel to Carbon, Alloy, Duplex, and Nickel Alloys with Product Pipes, Tubes, Bars we serve the world’s most demanding industries with trust, traceability, and timely delivery.

(Structured to mirror the “Seamless Pipe vs Welded Pipe” table from your sample.)

| Feature | ERW Pipes | EFW Pipes | LSAW / HSAW (SAW) | Spiral Welded |

|---|---|---|---|---|

| Manufacturing Method | Electric resistance | Electric fusion | Submerged arc weld | Submerged arc weld (spiral) |

| Diameter Range | Small–Medium | Medium | Medium–Large | Large–Very Large |

| Pressure Handling | Low–Medium | Medium–High | Very High | High |

| Corrosion Resistance | Moderate | Excellent | Depends on grade | Depends on grade |

| Applications | Water, air, structural | Chemical, refinery, SS service | Oil, gas, water pipelines | Water lines, piling |

| Cost | Lowest | Moderate | Moderate–High | Low–Moderate |

Each welded pipe type has a targeted industrial purpose:

We supply welded pipes in:

Standards Covered:

These dimensional and welding standards ensure compatibility with refinery, structural, offshore, city water, and power plant requirements across India, GCC, Africa, Europe, and the Americas.

Stainless Steel Welded Pipes are widely used for corrosive, hygienic, and high-temperature applications. Manufactured from superior quality SS coils and welded using ERW/EFW/SAW technologies, these pipes ensure excellent corrosion resistance and long-term durability.

Grades Offered:

SS 304, 304L, 316, 316L, 310, 321, 347

Why buyers choose SS Welded Pipes:

Applications:

Refineries • Chemical plants • Food industry • Pharma pipelines • Heat exchanger shells

Carbon Steel Welded Pipes dominate structural, water transmission, and low–medium pressure pipelines. Manufactured via ERW or SAW processes, they offer the best balance of strength, availability, and affordability.

Grades Offered:

ASTM A53 Gr A/B, IS 3589 Class A/B/C, API 5L Gr B–X70

Advantages:

Applications:

PEB structures • Water pipelines • Fire-fighting lines • Industrial fabrication

Alloy Steel Welded Pipes are designed for high-temperature and high-pressure service. Manufactured using SAW with chrome-moly plates, they ensure stability and creep resistance at elevated temperatures.

Typical Grades:

P1, P5, P9, P11, P22, P91

Why engineers choose Alloy Steel Welded Pipes:

Applications:

Superheater lines • Boiler piping • Steam distribution • Furnace tubes

Nickel Alloy Welded Pipes represent high-performance materials used for extreme corrosion, high heat, and aggressive chemicals.

Common Grades:

Inconel 600/625 • Monel 400 • Hastelloy C22/C276

Advantages:

Applications:

Desalination • Chemical reactors • Marine systems • Aerospace components

Duplex microstructure (ferritic + austenitic) gives these pipes twice the strength of standard stainless steel with superior chloride resistance.

Grades:

S31803 / S32205 (Duplex)

S32750 / S32760 (Super Duplex)

Used in:

Offshore platforms • Heat exchangers • Petrochemical plants • Desalination lines

Known for exceptional corrosion resistance in seawater and marine environments.

Why Cu-Ni?

Applications:

Shipbuilding • Cooling systems • Heat exchangers • Fire-fighting lines

Titanium Welded Pipes offer unmatched strength-to-weight ratio and corrosion resistance for demanding sectors.

Applications:

Power plants • Aerospace • Marine systems • Chemical reactors

| Standard Code | Description / Material Scope | Common Grades Supplied |

|---|---|---|

| ASTM A312 / SA312 | Stainless Steel Welded Pipes | TP304, TP316L |

| ASTM A358 / SA358 | EFW Stainless Steel Pipe | Class 1–5 (SS Grades) |

| ASTM A53 / SA53 | Carbon Steel ERW Pipes | Gr A, B |

| ASTM A671 / A672 | SAW Pipes for Low-Temp & Pressure | CC60, CC65, CC70 |

| ASTM A691 | Alloy Steel SAW Pipes | P1, P5, P9, P11, P22, P91 |

| API 5L | Line Pipes for Oil & Gas | Gr B, X42–X80 |

| EN 10217 | Welded steel tubes for pressure service | P235TR1, P265TR2 |

| IS 3589 | MS ERW Pipes (Water Pipelines) | Class A/B/C |

| IS 1239 | MS ERW Pipes (General Engineering) | Class A/B/C |

| BS 3601 / 3602 | CHS for structural use | Various CS grades |

Precise OD/ID Smooth weld Ideal for water, air, low–medium pressure

Premium welding for SS & alloys Exceptional corrosion resistance Suitable for chemical & food-grade service

Deep weld penetration Perfect for oil & gas + high-pressure lines Available in large diameters

Cost-effective for long-length water pipelines Flexible diameter range

Used for custom diameters & special applications

Welded pipes are installed wherever fluids, gases, steam, or structural loads need reliable and economical support.

Talk to our experts for technical support, pricing, and bulk orders.

Welded pipe prices vary depending on type (ERW / EFW / SAW / Spiral), material (CS / SS / Alloy / Duplex), wall thickness, and project specifications.

Below is an indicative price matrix:

| Material / Type | Size Range | Approx. Price (₹/kg) | Approx. Price (USD/kg) |

|---|---|---|---|

| ERW MS Pipes (IS 1239 / IS 3589) | ½″ – 24″ | ₹58 – ₹75 | $0.70 – $0.92 |

| EFW Stainless Steel Pipes (A312 / A358) | 1″ – 24″ | ₹260 – ₹550 | $3.3 – $6.8 |

| LSAW SAW Pipes (A671 / A672) | 18″ – 120″ | ₹80 – ₹135 | $1.0 – $1.65 |

| HSAW Spiral Welded Pipes | 20″ – 144″ | ₹65 – ₹110 | $0.78 – $1.35 |

| Alloy Steel Welded Pipes (A691) | 8″ – 48″ | ₹180 – ₹420 | $2.2 – $5.2 |

| Duplex / Super Duplex Welded Pipes | 1″ – 24″ | ₹600 – ₹900 | $7.5 – $11.0 |

Prices depend on origin (JSW, Jindal SAW, Welspun, Ratnamani), coating requirements, and project-based approvals.

Bulk buyers can request CIF/FOB rates with complete documentation support.

| Industry / Process | Typical Standards & Grades | Purpose / Application |

|---|---|---|

| Process Piping | ASTM A312 / A358 | Chemical, refinery & industrial fluid transport |

| Oil & Gas Pipelines | API 5L / A671 / A672 | Long-distance crude & gas lines |

| High-Temperature Service | ASTM A691 (P11 / P22 / P91) | Steam, superheaters, furnace lines |

| Low-Temperature Service | ASTM A672 / EN 10217 | LNG, cryogenic systems |

| High-Pressure Service | A671 / A672 / A691 | Boiler feedwater, power plant circuits |

| Structural Applications | IS 3589 / BS 3601 | Columns, trusses, platforms |

| Water Transmission | IS 3589 / Spiral Welded | City water, irrigation, desalination |

| Refinery & Petrochemical | A312 / A358 / A409 | Reactor lines, heat exchanger shells |

| Power & Energy | A691 / A672 | Turbine piping, condensate systems |

| Utility & Fire-Fighting Lines | ERW / IS 1239 | Hydrant lines, sprinkler mains |

We export ERW, EFW, LSAW, HSAW, and Spiral Welded pipes to:

Each export shipment includes EN 10204 3.1/3.2 MTC, third-party inspection options (TÜV/SGS/BV/LR), protected end caps, and seaworthy packaging.

We support EPC contractors, government tenders, private industrial projects, and OEM manufacturers with long-term welded pipe solutions.

52-A, Mulji Thackersi Bldg, Islampura Street, Shop No. 10, Near Alankar Cinema, Mumbai – 400 004

info@inoxsteelindia.com

+91 9820920268

ERW, EFW, LSAW, HSAW, Spiral Welded, and Fabricated Welded Pipes.

A312, A358, A53, A671, A672, A691, API 5L, EN 10217, IS 3589, IS 1239.

Yes — SAW (A671/A672) and Alloy Welded Pipes (A691) are widely used for high-pressure and high-temperature services.

½″ to 144″ diameter with thickness up to 80 mm.

ERW uses electric resistance and is ideal for small–medium sizes, while SAW uses submerged arc welding for large diameters and high-pressure service.

Yes — EN 10204 3.1/3.2 MTC, TPI (TÜV/BV/SGS) available.

Yes — Gulf, Africa, Europe, Americas, and Asia-Pacific.

WhatsApp us