Home > Hollow Sections

In the world of structural engineering and fabrication, Hollow Sections represent the most balanced combination of strength, weight efficiency, and clean geometry. A hollow section is a cold-formed or hot-finished steel tube available in three primary shapes:

Unlike conventional solid sections, hollow sections offer superior load distribution, excellent torsional resistance, aesthetic appearance, and uniform strength across the structure. This makes them the preferred choice for:

Engineers choose CHS/SHS/RHS when they require structural reliability, high bending resistance, reduced weight, and long operational life. These sections are manufactured as per IS 4923, EN 10219, EN 10210, ASTM A500, and IS 1161, ensuring consistent mechanical properties, dimensional accuracy, and weldability.

From multi-storey buildings to solar EPC projects, from warehouse frames to bus-body and trailer chassis, Hollow Sections have become a universal structural material trusted across India, GCC, Africa, Europe, and Asia.

Hollow Sections are manufactured through either cold forming or hot finishing processes, depending on the required mechanical performance.

These are produced by forming steel coils into CHS/SHS/RHS shapes followed by high-frequency welding, sizing, and straightening. They offer:

These are formed at elevated temperatures and normalized post-manufacturing, ensuring:

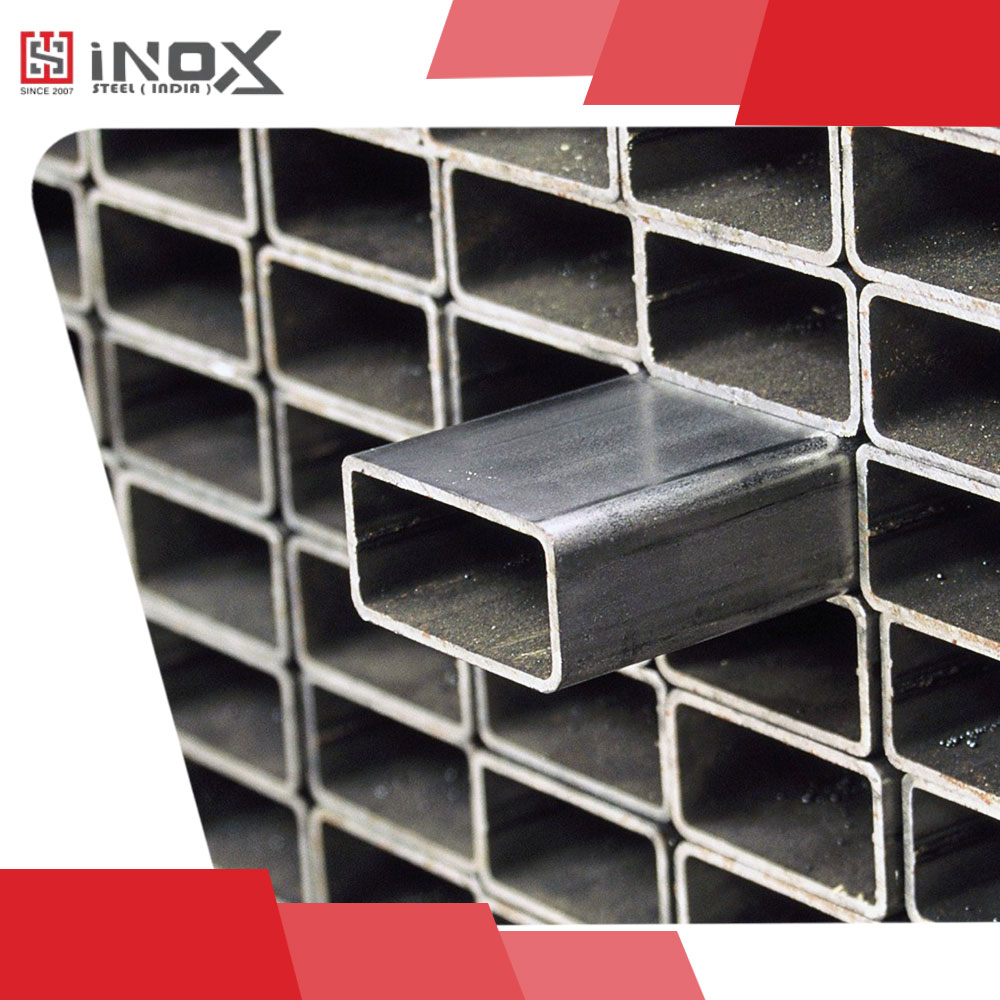

RHS is widely preferred for structures that demand strong axial load capacity, excellent bending resistance, and easy integration into fabricated assemblies. The flat surfaces and optimized corner radii of RHS make it particularly suitable for PEB structures, solar mounting systems, heavy industrial frameworks, and civil infrastructure.

With over a decade of experience and multi-material capability — from Stainless Steel to Carbon, Alloy, Duplex, and Nickel Alloys with Product Pipes, Tubes, Bars we serve the world’s most demanding industries with trust, traceability, and timely delivery.

| Feature | CHS — Circular | SHS — Square | RHS — Rectangular |

|---|---|---|---|

| Shape | Round | Square | Rectangular |

| Load Distribution | Best for torsion | Balanced | Best for bending |

| Aesthetic Use | High | Medium | Medium |

| Strength-to-Weight | Highest | High | High |

| Applications | Architectural, handrails | Frames, supports | Beams, rafters |

| Fabrication | Easy to roll/bend | Easy to cut & weld | Strong for spans |

👉 Verdict:

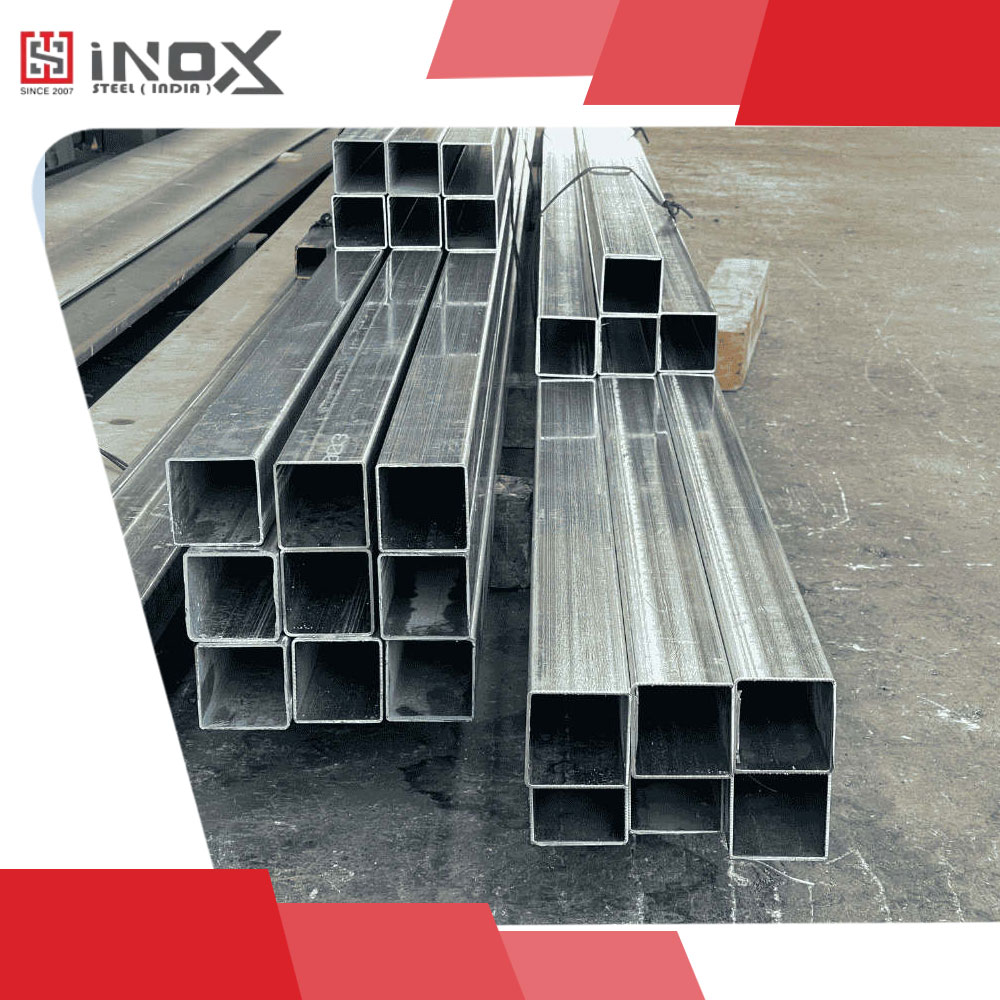

All three shapes serve different structural needs.

We supply Hollow Sections from:

Wall Thickness Range: 1.6 mm to 16 mm

Lengths Available: 6 meters, 12 meters, and custom cut-to-length

Standards Covered:

Common Grades:

We also provide weight charts, size charts, and load tables to help engineers calculate structural performance.

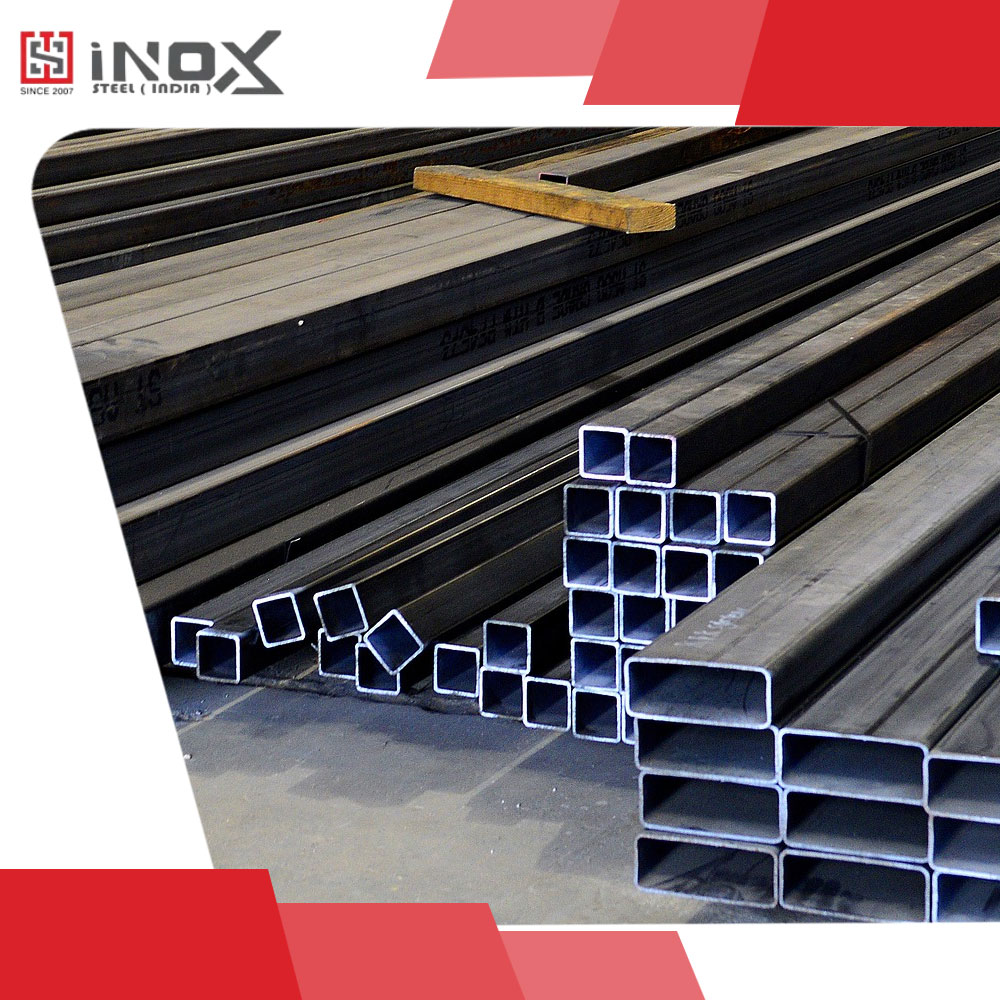

Mild Steel Hollow Sections are the most widely used category across fabrication and construction due to their balanced strength, excellent weldability, and cost-efficiency. Manufactured under IS 4923 / IS 1161, they are the backbone of structural frames, industrial sheds, and machinery columns.

Why engineers choose MS Hollow Sections:

Typical use:

Warehouse frames • MS sheds • Fabrication units • OEM structures • Support frames

Carbon Steel Hollow Sections offer superior strength and enhanced mechanical performance for heavy-duty structural applications. Manufactured as per EN 10210 and EN 10219, these sections are preferred when high load-bearing capacity and durability are required.

Grades Offered:

Why engineers prefer Carbon Steel:

Used in:

PEB structures • Industrial sheds • Machinery supports • Bridges • Heavy frameworks

Carbon Steel Hollow Sections offer superior strength and enhanced mechanical performance for heavy-duty structural applications. Manufactured as per EN 10210 and EN 10219, these sections are preferred when high load-bearing capacity and durability are required.

Grades Offered:

Why engineers prefer Carbon Steel:

Used in:

PEB structures • Industrial sheds • Machinery supports • Bridges • Heavy frameworks

Stainless Steel Hollow Sections are used where aesthetic appearance + corrosion resistance are essential. Manufactured per ASTM A554 / EN 10296, these tubes offer long life in aggressive and hygiene-sensitive environments.

Why buyers choose SS Hollow Sections:

Typical use:

Architectural structures • Railing frames • Designer furniture • Facades • Marine zones

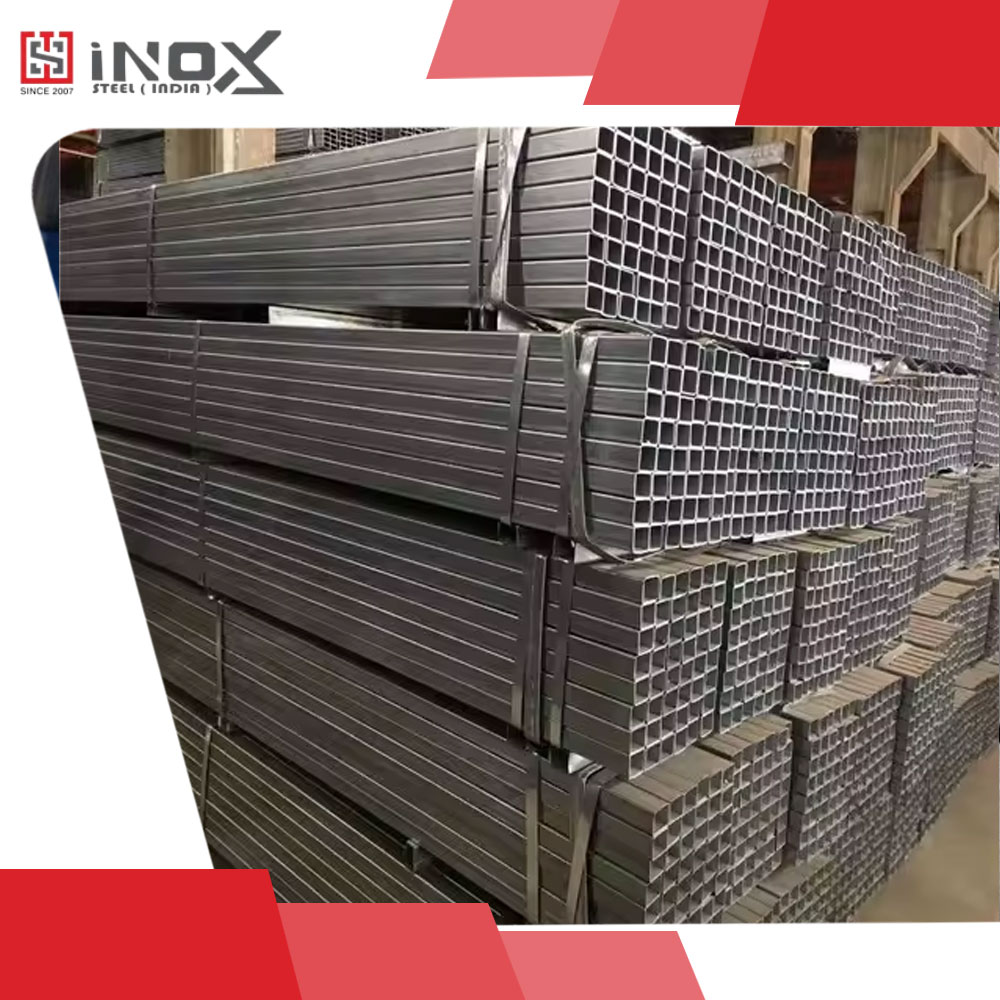

Galvanized Hollow Sections are ideal for outdoor and high-moisture applications. Hot-dip or pre-galvanized coatings provide superior corrosion resistance, making them indispensable for solar and canopy structures.

Why engineers prefer GI Hollow Sections:

Used in:

Solar mounting • Carports • Outdoor frames • Greenhouse structures • Lighting poles

| Standard Code | Description / Material Scope | Common Grades Supplied |

|---|---|---|

| IS 4923 | Hot/Cold formed SHS & RHS for structural use | YST 210 / 240 / 310 |

| IS 1161 | Structural steel tubes – circular | YST 210 / 240 |

| EN 10219 | Cold-formed hollow sections | S235JRH / S275J0H |

| EN 10210 | Hot-finished hollow sections | S355J2H |

| ASTM A500 | North American structural tubing | Gr A, B, C |

| IS 3601 | Steel tubes for structural purposes | YST grades |

This ensures compatibility with Indian, European, and American project specifications.

Circular Hollow Sections (CHS)

Square Hollow Sections (SHS)

Rectangular Hollow Sections (RHS)

Talk to our experts for technical support, pricing, and bulk orders.

Hollow Sections are used wherever strong, versatile, and lightweight structural members are required. Typical applications include:

Inox Steel India Located in Mumbai with ready stock of CHS/SHS/RHS in MS, CS, SS & GI, we supply hollow sections that meet global structural requirements.

We support EPC contractors, fabrication companies, PEB builders, and OEM manufacturers with reliable hollow section supply.

Hollow Sections (CHS / SHS / RHS) prices vary based on material, wall thickness, size, and coating type (MS / CS / GI / SS). Below is an indicative price range for standard grades:

| Material / Type | Typical Size Range | Approx. Price (₹/kg) | Approx. Price (USD/kg) |

|---|---|---|---|

| MS Hollow Sections (CHS/SHS/RHS) | 15×15 to 300×300 | ₹62 – ₹78 | $0.75 – $0.95 |

| GI Hollow Sections (Hot Dip / Pre-GI) | 20×20 to 250×250 | ₹72 – ₹95 | $0.88 – $1.15 |

| Carbon Steel (EN 10210/10219) | 40×40 to 300×200 | ₹70 – ₹105 | $0.90 – $1.25 |

| Stainless Steel Hollow Sections | 20×20 to 200×100 | ₹220 – ₹450 | $3.2 – $6.0 |

Prices fluctuate depending on coil origin (AMNS, JSW, TDC, Jindal), zinc coating (for GI), grade selection, and project quantity.

Bulk buyers, EPC contractors, and long-term fabricators can request special CIF/FOB pricing with MTC certification.

| Industry / Application | Typical Standard & Grade | Purpose / Use |

|---|---|---|

| Construction & PEB Structures | IS 4923 YST 240 / EN 10219 S235JRH | Columns, rafters, trusses |

| Industrial Fabrication & OEMs | IS 1161 YST 210 / EN 10210 S355J2H | Machine frames, equipment supports |

| Solar EPC & Canopy Structures | GI / Pre-GI Sections | Solar mounting, carports, light structures |

| Furniture & Architectural | SS 304 / SS 316 / MS | Designer frameworks, facades, railings |

| Automotive & Transport | IS 4923 YST 310 | Bus body, trailer chassis, trolleys |

| Signage & Outdoor Structures | GI / Hot-Dip Galvanized | Poles, towers, frames |

We export CHS, SHS, and RHS across:

Every shipment includes EN 10204 3.1 MTC, full traceability, and packaging suitable for export containers.

Every Hollow Section supply is accompanied by:

Heat number, batch number, and grade are stamped for full traceability.

We are trusted by fabricators, EPC companies, building contractors, solar integrators, automotive units, and machinery manufacturers.

52-A, Mulji Thackersi Bldg, Islampura Street, Shop No. 10, Near Alankar Cinema, Mumbai – 400 004

info@inoxsteelindia.com

+91 9820920268

They are used for structural frames, industrial fabrication, solar mounting, automotive bodies, and architectural applications.

CHS (Circular), SHS (Square), and RHS (Rectangular).

IS 4923 (SHS/RHS) and IS 1161 (CHS).

YST 210 / 240 / 310 and European grades S235JRH / S355J2H.

Yes — Hot-Dip GI and Pre-GI sections are supplied for outdoor use.

CHS: 21.3–508 mm OD

SHS: 15×15–300×300 mm

RHS: 20×10–400×200 mm

Yes, to GCC, Africa, Europe, America, and Asia-Pacific regions.

WhatsApp us