Home > Forged Bars

Forged Bars are high-strength metal bars produced by compressive deformation of billets or ingots under controlled temperature and pressure. This forging process aligns the grain flow, eliminates porosity, enhances toughness, and significantly increases fatigue resistance.

Forged Bars are used where high mechanical strength, structural integrity, impact resistance, and reliability under extreme conditions are mandatory. Unlike hot rolled or bright bars, forged bars offer:

Forged Bars are widely produced in Carbon Steel, Alloy Steel, Stainless Steel, Duplex/Super Duplex, Nickel Alloys, Copper Alloys, and Titanium — enabling use across the most demanding industries.

Forging is performed through specialized processes that drastically improve mechanical performance:

With over a decade of experience and multi-material capability — from Stainless Steel to Carbon, Alloy, Duplex, and Nickel Alloys with Product Pipes, Tubes, Bars we serve the world’s most demanding industries with trust, traceability, and timely delivery.

| Feature | Forged Bars | Hot Rolled Bars | Bright Bars |

|---|---|---|---|

| Strength | Highest | High | Moderate–High |

| Grain Flow | Aligned | Random | Random |

| Internal Integrity | 100% sound | May contain inclusions | Excellent finish, but not forged strength |

| Fatigue Resistance | Exceptional | Good | Good |

| Applications | Extreme-duty uses | Structural | Machining |

👉 Conclusion:

Forged Bars = the strongest product form for extreme mechanical loads.

We supply forged bars in:

Standards Covered:

Carbon Steel Forged Bars offer excellent strength, toughness, and weldability — making them ideal for heavy engineering, structural applications, pressure-containing components, and power generation equipment.

Common Grades:

A105 • A350 LF2 • C45 • EN8 • EN9

Advantages:

Applications:

Pressure vessel components • Flanges • Shafts • Rings • Heavy machinery parts

Alloy Steel Forged Bars are used for critical-duty components requiring impact resistance, fatigue strength, and the ability to operate at high temperatures.

Common Grades:

4140 • 4130 • 4340 • EN19 • EN24 • A182 F11/F22/F91

Key Benefits:

Applications:

Power plant shafts • Turbine components • Oilfield tools • Transmission parts

Stainless Steel Forged Bars are corrosion-resistant, strong, and used heavily in chemical plants, marine applications, food processing, pharmaceutical machinery, and high-temperature environments.

Grades:

304 • 304L • 316 • 316L • 321 • 347 • 410 • 420 • 431

Applications:

Pump shafts • Valve internals • Heat exchanger supports • Marine components

Duplex & Super Duplex Forged Bars provide exceptional chloride stress corrosion resistance, making them excellent for offshore, desalination, and chemical industries.

Grades:

S31803 • S32205 • S32750 • S32760

Applications:

Subsea components • Pump shafts • High-pressure valves • Offshore connectors

Nickel Alloy Forged Bars are designed for extreme conditions such as high temperatures, corrosive chemicals, and aggressive gas environments.

Grades:

Inconel 600 • 625 • 718 • Monel 400 • Hastelloy C22 • C276

Applications:

Aerospace • Petrochemical reactors • Furnace parts • Turbine hardware

Copper-based forged bars offer excellent conductivity, ductility, and resistance to seawater corrosion.

Applications:

Marine components • Valve parts • Electrical connectors • Heat transfer systems

Titanium Forged Bars deliver unmatched strength-to-weight ratio, biocompatibility, and corrosion resistance.

Grades:

Grade 2 • Grade 5 (Ti-6Al-4V)

Applications:

Aerospace • Defence • Subsea components • Medical implants

| Standard | Material Scope | Common Grades |

|---|---|---|

| ASTM A182 | Alloy & Stainless Steel Forgings | F11, F22, F91, 304, 316 |

| ASTM A105 | Carbon Steel Forgings | A105 |

| ASTM A350 | Low Temp Carbon Forgings | LF2 |

| ASTM B637 | Nickel Alloy Forgings | Inconel 718 |

| ASTM B564 | Nickel Alloy Bars & Forgings | Monel, Hastelloy, Inconel |

| ASTM B381 | Titanium Forgings | Grade 2, Grade 5 |

| EN 10222 | Steel Forgings | C45, 42CrMo4, 34CrNiMo6 |

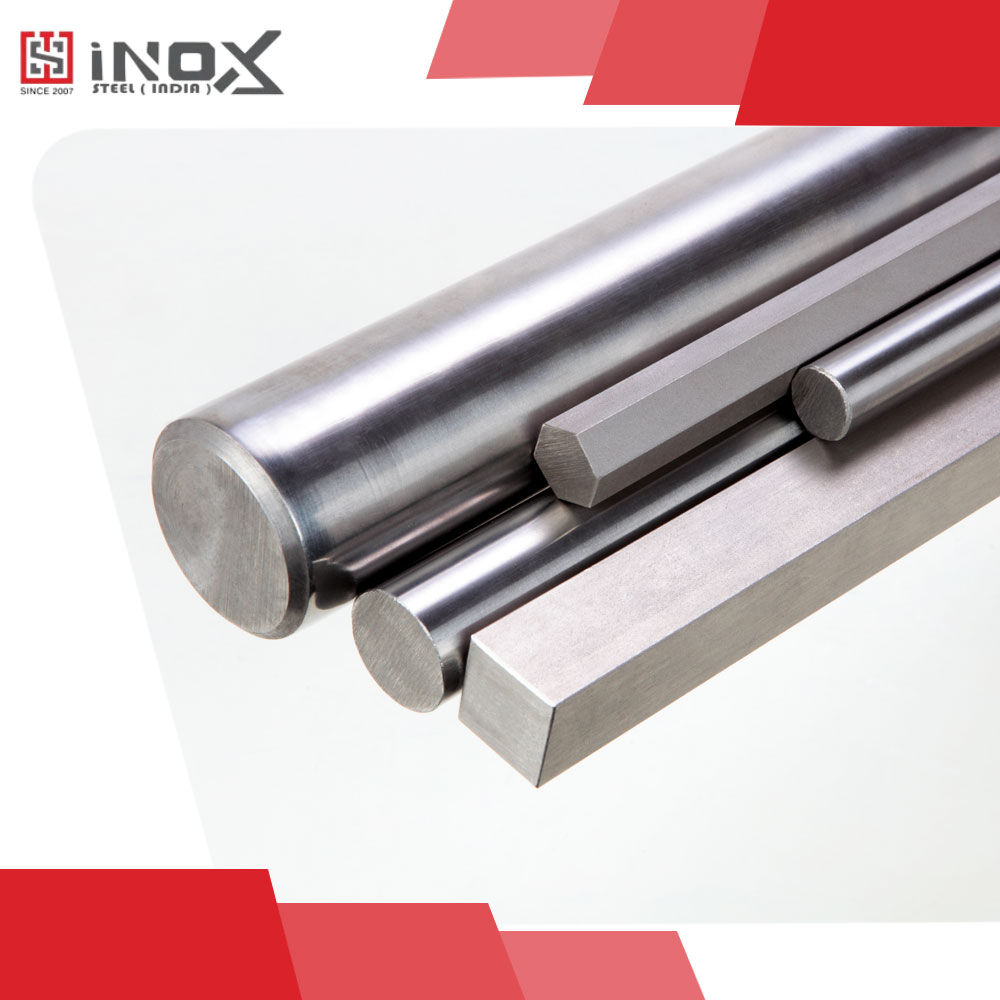

Forged Round Bars

Forged Square Bars

Forged Flat Bars

Custom Forged Shapes Bars

Rough Machined Forged Bars

Pressure Vessel Components

Power & Energy Sector

Oil & Gas Industry

Marine & Offshore

Aerospace & Defence

Talk to our experts for technical support, pricing, and bulk orders.

Pricing depends on material, diameter/size, forging method, rough-machined or as-forged, and certification requirements.

| Material / Type | Size Range | Approx. Price (₹/kg) | Approx. Price (USD/kg) |

|---|---|---|---|

| Carbon Steel Forged Bars | 50–600 mm | ₹75 – ₹150 | $0.9 – $1.9 |

| Alloy Steel Forged Bars (EN19 / EN24 / 4140 / 4340) | 50–500 mm | ₹130 – ₹300 | $1.7 – $3.8 |

| Stainless Steel Forged Bars (304 / 316 / 321) | 50–400 mm | ₹220 – ₹550 | $2.7 – $6.5 |

| Duplex / Super Duplex Forged Bars | 50–300 mm | ₹450 – ₹1200 | $5.6 – $15.0 |

| Nickel Alloy Forged Bars (Inconel / Monel / Hastelloy) | 50–250 mm | ₹1800 – ₹4200 | $22 – $55 |

| Copper / Brass / Bronze Forged Bars | 50–200 mm | ₹500 – ₹1400 | $6 – $17 |

| Titanium Forged Bars (Grade 2 / 5) | 50–200 mm | ₹1800 – ₹3500 | $22 – $42 |

⚠ Prices vary based on heat treatment, certifications, forging tolerances, and rough-machined vs fully forged supply.

| Application Segment | Suitable Materials | Used For |

|---|---|---|

| Pressure Vessel Components | CS, Alloy, SS | Flanges, rings, nozzle necks |

| Power & Energy | Alloy, SS, Nickel | Turbine shafts, boiler parts |

| Oil & Gas Industry | Alloy, Duplex, Nickel | Subsea blocks, valve parts |

| Marine & Offshore | SS 316, Duplex, Titanium | Pump shafts, corrosion-resistant components |

| Aerospace & Defence | Nickel, Titanium | Engine hardware, structural parts |

Forged Bars are exported to customers requiring high-strength, certified, heavy-duty metallurgical components.

Exports include EN 10204 3.1 / 3.2, forging route documentation, heat treatment charts, and seaworthy packing.

We offer complete metallurgical testing for forged bars:

Optional TPI: SGS, TÜV, DNV, Lloyd’s, BV.

52-A, Mulji Thackersi Bldg, Islampura Street, Shop No. 10, Near Alankar Cinema, Mumbai – 400 004

info@inoxsteelindia.com

+91 9820920268

Forged Bars are used for high-strength applications such as pressure vessels, turbine shafts, pump shafts, oil & gas subsea parts, and aerospace components.

Carbon Steel, Alloy Steel, Stainless Steel, Duplex/Super Duplex, Nickel Alloys, Copper Alloys, and Titanium.

Forging aligns grain flow, increases mechanical strength, and eliminates internal defects — making components stronger and more reliable.

Yes — rough-machined bars are available for OEMs to reduce machining time.

EN 10204 3.1/3.2 MTC, heat treatment charts, UT reports, PMI test, and mechanical test results.

Yes — we export to GCC, Europe, Africa, Americas, and Asia-Pacific.

Round, Square, Flat, Custom shapes, and near-net forged profiles.

WhatsApp us