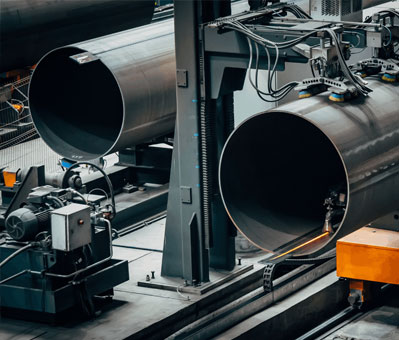

Your Trusted Partner for Seamless Pipes, Welded Pipes, Tubes & Engineering Materials

Inox Steel India is a professionally managed supplier of seamless pipes, welded pipes, tubes, hollow sections, and engineering bars for critical applications across Oil & Gas, Power, Chemical, Petrochemical, Marine, Pharma, Food, and Infrastructure sectors.

We operate with a simple belief:

Quality is not negotiable, and reliability is the foundation of every long-term partnership.

From stainless steel and carbon steel to high-performance alloys like Duplex, Super Duplex, Nickel Alloys and Titanium, we support engineering teams, EPC contractors, OEMs and project buyers with material that performs exactly as required—every time.

Decades of technical know-how, strong global sourcing, and a deep understanding of real-world project constraints make us a dependable partner for shutdowns, tenders, maintenance, and greenfield/brownfield projects.

Inox Steel India began with a clear purpose — to create a supply partner that engineers and procurement teams could trust without second thoughts.

What started as a small operation supplying stainless steel has grown into a multi-material, multi-standard, globally connected engineering supply company. The journey has been shaped by one principle:

Over the years, we have supported refineries, power plants, chemical units, fabrication shops, EPC contractors, OEM machine builders, marine yards and infrastructure projects across India and overseas. Each project, big or small, strengthened our belief that the industry needs suppliers who are technically competent, documentation-strong, and consistently reliable.

Today, Inox Steel India stands as a preferred partner because we do more than ship material

we understand applications, anticipate challenges, and support our clients like an engineering team member.

At Inox Steel India, quality is not an inspection step — it is our operating culture.

Every pipe, tube, fitting or bar that leaves our facility represents our name, and we treat that responsibility with absolute seriousness.

Our quality philosophy is built on four fundamentals:

We work only with mills and manufacturers that follow strict global standards, maintain traceability and pass our internal audits.

If a mill does not meet our criteria, we do not source from them — no exceptions.

From EN 10204 3.1 MTCs to heat charts, pressure ratings, chemical compositions and compliance reports—

we supply complete, correct and transparent documentation every time.

Material is packed, preserved and handled with care to ensure it reaches the site in project-ready condition, without damage or deviation.

Our commitment is simple:

If we wouldn’t install it in our own project, we won’t supply it to yours.

we supply complete, correct and transparent documentation every time.

From stainless steel and carbon steel to nickel alloys, duplex, super duplex and titanium —

we supply complete material solutions under one roof.

No multi-vendor complexity. No sourcing uncertainty.

Every item passes through strict inspections, testing and documentation checks.

If it is not 100% compliant, it does not leave our facility.

⚙ Technical Guidance That Reduces Risks.

We help clients choose the right grade, schedule, standard and specification based on:

This ensures correct material selection and eliminates costly errors.

Our ready stock, organised warehousing and strong logistics network help meet:

On-time delivery is our commitment.

Every supply includes complete MTCs, heat numbers, compliance certificates and inspection reports – giving QA/QC teams full transparency and zero dispute material.

Most of our clients work with us for years.

We value trust more than order size, which is why we support:

For us, supplying material is a responsibility, not a sale.

We ship regularly to:

UAE, Saudi Arabia, Oman, Qatar, Kuwait, Bahrain, Africa, Europe, Singapore, Malaysia and more.

Packing, fumigation, container loading and documentation are handled with care and precision.

A visionary with deep experience in the metals and engineering materials industry, Mr. founded Inox Steel India with a commitment to transparency, quality and long-term relationships.

He personally ensures that every order—big or small—meets the technical and documentation expectations of EPC contractors, OEMs and global buyers.

His strength lies in combining technical knowledge, market insight and mill relationships, enabling the company to support projects even under tight deadlines or challenging specifications.

Clients value his honesty, clarity and the confidence he brings to every supply.

A process-driven leader, she oversees our quality systems, inspections, documentation flow and warehouse operations.

She has implemented strict protocols for:

Her discipline ensures our deliveries maintain zero deviation and zero compromise.

Under her leadership, Inox Steel India has achieved exceptional accuracy in documentation and compliance.

With strong partnerships across leading mills in India, Europe, Korea and Japan, he ensures the availability of critical alloys, special grades and project-specific materials.

He manages:

His ability to navigate global supply chains ensures smooth deliveries to UAE, Saudi Arabia, Oman, Qatar, Africa, Europe and Southeast Asia.

A materials engineer with hands-on application knowledge, he supports clients with:

He bridges engineering and supply—reducing site delays, rejections and costly replacements.

At Inox Steel India, certifications are more than formal documents — they are a reflection of system discipline, quality assurance and global credibility.

Every process, from sourcing to dispatch, follows strict international standards.

Quality Management System

We operate through documented, controlled and continuously improved procedures.

This ensures:

Environmental Management System

We follow responsible practices in material handling, waste management and storage.

Our operations are designed to minimise environmental impact and maintain safe, organised work environments.

Occupational Health & Safety

Safety is integrated into warehouse handling, lifting operations, loading, storage and packaging.

Our team undergoes regular training to ensure safe working conditions and accident-free operations.

3.1 / 3.2 Mill Test Certificates

Every supply is accompanied by comprehensive MTCs covering:

3.2 certification (via third-party inspection agencies) is provided when required.

(TPI) Support

We coordinate with major inspection bodies, including:

This ensures unbiased verification for project-critical material.

Documentation Standards

For global shipments, we follow:

Our compliance framework ensures material is accurate, traceable and ready for audit at any time.

Our infrastructure is designed to support high-volume stock management, precise quality control, and fast project-based deliveries.

Every element of our facility is built around reliability, accuracy and efficiency.

We maintain a well-organised, temperature-appropriate warehouse with:

Our structured layout ensures fast picking, accurate dispatch and minimal lead time.

To ensure every dispatch meets global standards, we perform:

Each step is documented and cross-verified with purchase specs and MTCs.

We support project-specific requirements such as:

This capability is essential for EPC contractors and OEM buyers handling complex systems.

Our facility is optimised for global shipments with:

Our operational discipline ensures smooth movement from warehouse to the client’s site—anywhere in the world.

We supply materials that operate reliably in demanding, high-pressure, high-temperature and corrosive environments.

Our pipes, tubes and engineering alloys are used across a wide range of industries where safety, durability and compliance are non-negotiable.

Materials for pipelines, process piping, heat exchangers, separators, platforms and refinery systems.

Our alloy steel, carbon steel, duplex & nickel alloys are trusted for high pressure and sour service environments.

Solutions for thermal plants, gas-based power units, boilers, superheaters, reheaters and turbine piping.

We supply high-temperature and creep-resistant grades like P11, P22, P91.

Corrosion-resistant materials for reactors, distillation units, condensers, heaters and high-temperature furnaces.

Nickel alloys, duplex & SS grades ensure long-life performance.

Sanitary & hygienic stainless-steel tubes for cleanability, corrosion resistance and compliance with food-grade requirements.

Grades include 304L, 316L, A270, EN 10217-7.

Electropolished, bright annealed, and high-purity tubes used in sterile processing, WFI, instrumentation & cleanroom systems.

Strict documentation and surface-quality control maintained.

Seawater-resistant alloys including Cu-Ni 90/10, 70/30, Duplex, Super Duplex for piping, cooling systems and marine structures.

Hollow sections, SHS/RHS/CHS, structural tubes and bars used for industrial buildings, frames, platforms and fabrication structures.

Precision tubes, hydraulic tubes, mechanical tubing and bars used in components, axles, shafts, machining and OEM equipment.

Corrosion-resistant stainless steel, duplex and titanium materials for brine lines, condensers, evaporators and high-salinity systems.

Heat exchanger, boiler, pressure vessel and process equipment manufacturers rely on our accurate OD/ID, schedules and material consistency.

Quality is built into every stage of our operations.

Our QC process ensures that every pipe, tube or bar we dispatch meets global standards, project specifications and real-world application demands.

We procure only from approved mills that meet:

Every mill is pre-audited for capability, consistency and reliability.

Once material reaches our warehouse, we verify:

No material enters stock without passing these checks.

Using reliable PMI instrumentation, we validate:

This eliminates grade-mismatch risks—critical for high-temperature, high-pressure and corrosive applications.

Depending on the type of pipe or tube, we conduct:

This ensures integrity, consistency and suitability for demanding applications.

Our QC team measures:

Visual inspection ensures the material is project-ready.

We cross-check:

Documentation must be 100% accurate before dispatch.

Once tests are completed, materials are:

This ensures full transparency for QC teams, auditors and consultants.

Materials are packed as per application:

We ensure the material reaches your site in perfect, installable condition.

Every supply is 100% tested, verified and traceable — exactly how engineering materials should be.

Inox Steel India has grown from a domestic supplier into a globally recognised export partner, supplying critical materials to engineering projects across multiple continents. Our international presence is built on consistent quality, reliable documentation and timely deliveries that meet strict project schedules.

Our global network continues to expand as more engineering companies choose us for credible sourcing and reliable project execution.

We export seamless pipes, welded pipes, tubes, hollow sections and engineering bars to:

Middle East / GCC

Africa

Europe

Asia & Far East

Other Regions

We follow strict export protocols to ensure damage-free, seaworthy shipments:

Each consignment is packed to withstand long transit times and varied climate conditions.

We provide complete documentation support including:

Our clients receive zero-error documentation, ensuring fast customs clearance and smooth site acceptance.

Engineering firms, distributors, EPC contractors and OEMs across GCC, Africa and Asia trust Inox Steel India because we deliver:

This has enabled us to become a preferred export partner for project-critical materials.

At Inox Steel India, we understand that the materials we supply are not just components —

they are the backbone of your plant, your pipeline, your pressure system, your safety and your reputation.

That is why every order is handled with the same seriousness, whether it is a small urgent requirement or a complete project package.

Our commitment is simple:

If it does not meet the required quality, it does not leave our warehouse.

From technical clarifications to documentation support and urgent dispatches —

we work as an extension of your engineering and procurement team.

Shutdowns, maintenance, project handovers, consultant approvals —

we understand the pressure and we respond with speed and clarity.

No hidden surprises.

No compromised quality.

No last-minute changes.

Because trust is earned not by what we say, but by what we deliver.

For us, supplying steel is not a transaction.

It is a promise that your system will run safely, efficiently and reliably.

This is the value we bring.

This is the partnership we stand for.

WhatsApp us