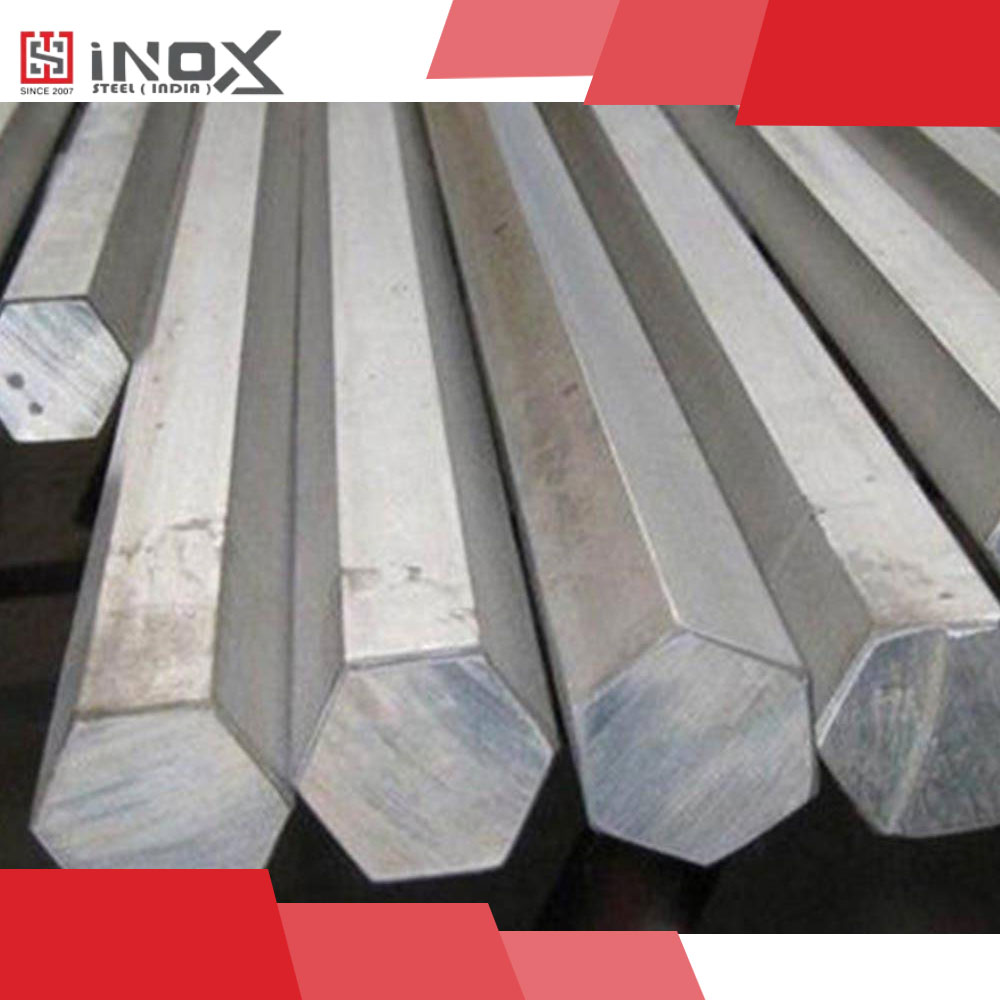

An alloy steel hex bar is a solid long product with a hexagonal (six-sided) cross section, manufactured from alloy steel containing chromium, molybdenum, and nickel (where applicable). The hexagonal profile provides positive spanner grip and torque transmission, making these bars suitable for high-strength fasteners, shafts, gears, and machined components.

Alloy steel hex bars are produced from alloy steel billets using hot rolling, cold drawing (bright bar processing), or forging, followed by heat treatment to achieve the required mechanical properties.

Inox Steel India is a manufacturer, supplier, and exporter of alloy steel hex bars, supplying to engineering, automotive, and industrial machinery sectors across India, GCC countries, the Middle East, Africa, Europe, and North & South America.

Alloy steel hex bars are supplied in EN19, EN24, and AISI 4140 grades, manufactured in accordance with EN 10083 and ASTM standards. These grades are selected for applications requiring high tensile strength, fatigue resistance, and load-bearing capability.

With controlled heat treatment and dimensional processing, alloy steel hex bars supplied by Inox Steel India offer consistent mechanical properties, uniform across-flat dimensions, and suitability for critical engineering applications.

These properties make alloy steel hex bars suitable for automotive, machinery, power transmission, and heavy engineering applications.

Alloy steel hex bars are supplied in the following grades:

EN19 (42CrMo4) – Chromium-molybdenum alloy steel for high-strength components

EN24 (AISI 4340) – Nickel-chromium-molybdenum alloy steel for heavy-duty applications

AISI 4140 – Chromium-molybdenum alloy steel for machinery and automotive parts

Materials are supplied as per EN 10083 and ASTM A29 / A322 specifications.

Refer to the approved Master Technical Data Sheet for chemical composition, mechanical properties, and standard hex bar sizes in mm.

Proper grade and condition selection ensures performance reliability and service life in demanding applications.

In India, alloy steel hex bars are widely used by automotive component manufacturers, gear and shaft manufacturers, CNC machining units, and heavy engineering industries, particularly in industrial regions such as Pune, Chennai, Bengaluru, Ahmedabad, and Ludhiana.

Export demand is driven by machinery, power transmission, and engineering components requiring EN and ASTM-compliant alloy steel bars.

Service Use: High-strength mechanical applications.

Typical Applications: Shafts, studs, bolts, gears, power transmission components.

Industry Sectors: Automotive | Machinery | Heavy Engineering

Service Use: Heavy-duty and high-impact applications.

Typical Applications: Aerospace components, heavy gears, crankshafts, high-load fasteners.

Industry Sectors: Aerospace | Defence | Heavy Machinery

Service Use: Medium to high-load engineering applications.

Typical Applications: Machine parts, automotive components, tool holders, structural fasteners.

Industry Sectors: Automotive | Industrial Machinery | Engineering

Alloy steel hex bars are supplied in standard metric hex bar sizes as per EN and ASTM tolerances.

| AF Size (mm) | Approx. Weight (kg/m) |

| 8 | 0.43 |

| 10 | 0.68 |

| 12 | 0.98 |

| 16 | 1.74 |

| 20 | 2.72 |

| 25 | 4.25 |

| 30 | 6.11 |

| 40 | 10.86 |

| 50 | 16.90 |

| 60 | 24.60 |

Weights are indicative and may vary based on tolerance and surface finish.

| Grade | Approx. Price Range (INR / kg) |

| EN19 | ₹ 110 – ₹ 160 |

| EN24 | ₹ 150 – ₹ 220 |

| AISI 4140 | ₹ 120 – ₹ 180 |

Prices vary based on size, heat-treatment condition (annealed / Q&T), finish (black / bright), quantity, and market conditions.

HSN Code: 7228

Material can be supplied with EN 10204 3.1 certification on request.

Whether you require EN19 hex bars for general engineering, EN24 hex bars for high-impact applications, or AISI 4140 hex bars for machinery and automotive parts, our team will assist with grade selection, pricing, and delivery schedules.

EN19, EN24, and AISI 4140 grades are available. Standard across-flat sizes range from 8 mm to 60 mm. Other sizes can be supplied on request. Yes, alloy steel hex bars can be supplied in annealed, normalized, or quenched & tempered condition. The applicable HSN code is 7228. Yes, alloy steel hex bars can be supplied in custom cut lengths as per requirement. Material can be supplied with EN 10204 3.1 certification on request. What grades are available in alloy steel hex bars?

What are the standard hex bar sizes in mm?

Are heat-treated alloy steel hex bars available?

What is the HSN code for alloy steel hex bars?

Are custom cut lengths available?

Is test certification provided with supply?

WhatsApp us