Home > Square Bars > Alloy Steel Square Bars

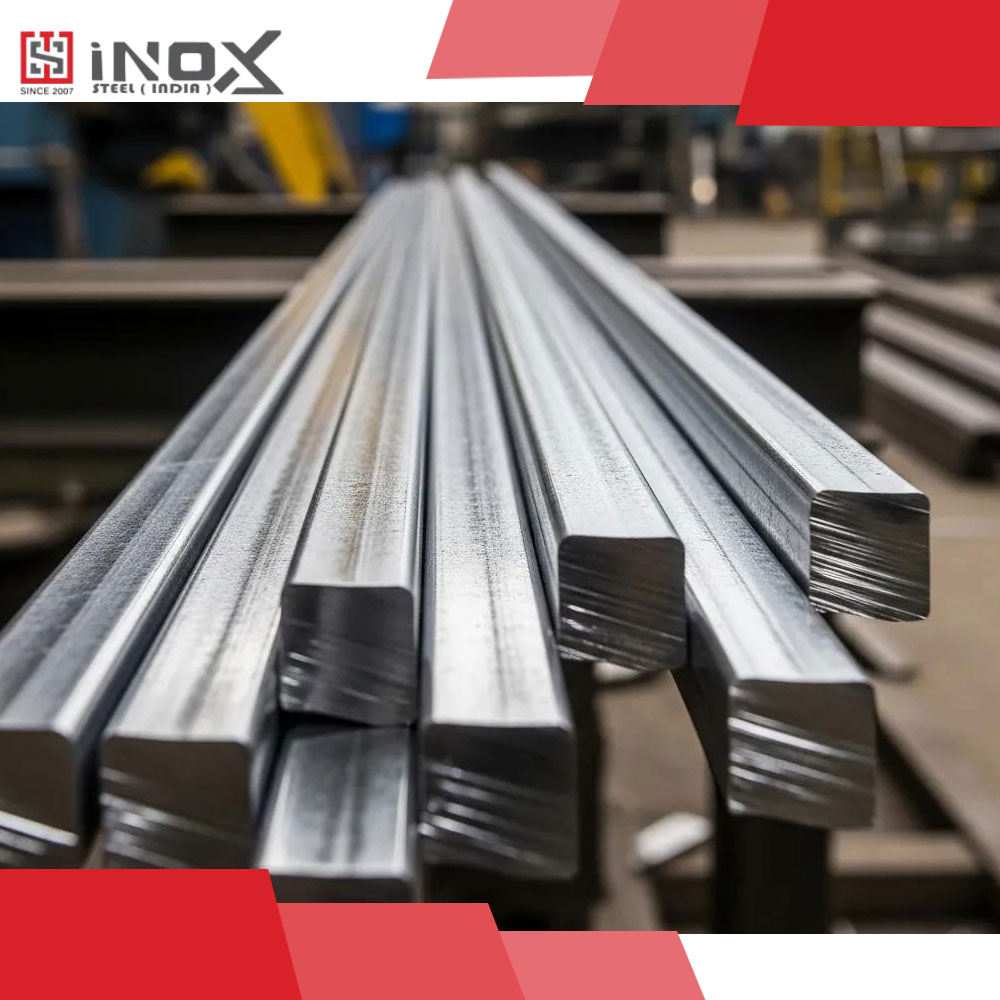

An alloy steel square bar is a solid steel bar with a square cross-section, manufactured by alloying carbon steel with elements such as chromium, molybdenum, and nickel to enhance strength, hardness, wear resistance, and fatigue life.

Alloy steel square bars are used in applications where:

The square geometry provides excellent torsional strength and flat reference surfaces, making these bars suitable for machining and precision fitting in mechanical systems.

Inox Steel India is a trusted manufacturer, supplier, stockist, and exporter of alloy steel square bars in India, supplying premium-quality EN19, EN24, and AISI 4140 square bars to heavy engineering, automotive, power transmission, forging, and OEM manufacturing sectors.

These alloy steel square bars are designed for applications where high strength, toughness, fatigue resistance, and wear performance are critical.

Compared to carbon steel square bars, alloy steel square bars offer superior mechanical strength, deeper hardenability, and better performance under dynamic and shock loads.

This makes them the preferred material for shafts, gears, axles, crank components, high-load machine parts, and precision-engineered assemblies.

All alloy steel square bars supplied by Inox Steel India are produced in accordance with EN 10083, ASTM A29, and AISI standards, ensuring consistent metallurgy, reliable performance, and compatibility with international engineering specifications.

Inox Steel India follows controlled manufacturing and processing methods to ensure alloy steel square bars meet demanding engineering requirements.

This process ensures uniform mechanical properties, excellent machinability, and long-term reliability in high-stress service conditions.

EN19 Alloy Steel Square Bars: Chromium–molybdenum alloy steel offering high strength, good toughness, and reliable machinability.

EN24 Alloy Steel Square Bars: Nickel–chromium–molybdenum alloy steel providing excellent impact strength and fatigue resistance.

AISI 4140 Alloy Steel Square Bars: Widely used international grade with balanced strength and wear resistance.

Standard Square Bar Sizes (mm):

8 | 10 | 12 | 16 | 20 | 22 | 25 | 30 | 32 | 35 | 40 | 45 | 50 | 60 | 65 | 70 | 75 | 80 | 100 | 120 | 150

Length: Random (3–6 m) or fixed cut lengths

Tolerance: As per EN / ASTM standards

Finish: Hot Rolled (Black), Bright Drawn (Cold Drawn)

| Square Size (mm) | Weight (kg/m) |

| 8 × 8 | 0.50 |

| 10 × 10 | 0.79 |

| 12 × 12 | 1.13 |

| 16 × 16 | 2.01 |

| 20 × 20 | 3.14 |

| 25 × 25 | 4.91 |

| 30 × 30 | 7.07 |

| 40 × 40 | 12.56 |

| 50 × 50 | 19.63 |

| 65 × 65 | 33.15 |

| 75 × 75 | 44.16 |

| 100 × 100 | 78.50 |

| Grade | Approx. Price / Kg (INR) | Typical Use |

| EN19 | ₹110 – ₹150 | Shafts, gears, axles |

| EN24 | ₹145 – ₹190 | Heavy-duty machine parts |

| AISI 4140 | ₹120 – ₹165 | High-stress components |

HSN Code (India): 7228.30.29

HS Code (Export): 7228.30

Certification: EN 10204 3.1 Mill Test Certificate

Third-Party Inspection: SGS / TUV / BV (on request)

| Industry | Application | Preferred Grade |

| Heavy Engineering | Shafts, gears, spindles | EN19 / 4140 |

| Automotive & OEM | Axles, drive components | EN24 |

| Power Transmission | Couplings, pinions | EN19 / EN24 |

| Forging Units | Forging stock | EN19 / EN24 |

| Machinery Manufacturing | High-stress parts | 4140 |

| Mining & Construction | Wear components | EN24 |

Whether you need EN19 for shafts, EN24 for heavy-duty components, or AISI 4140 for high-stress machinery, Inox Steel India offers certified quality, competitive pricing, and reliable delivery.

An alloy steel square bar is a solid square section steel alloyed with elements like chromium, molybdenum, and nickel to enhance strength, toughness, and wear resistance. EN24 is preferred for heavy-duty and impact-resistant components; EN19/4140 are widely used for shafts and gears. Yes, we supply quenched and tempered alloy steel square bars as per application requirements. Standard sizes range from 8 mm to 150 mm, with custom sizes and cut lengths available. The HSN code is 7228.30.29 for alloy steel bars and rods. Yes, all supplies are accompanied by EN 10204 3.1 Mill Test Certificates Yes, we regularly export to GCC, Africa, Europe, and Southeast Asia. What is an alloy steel square bar?

Which grade is best for heavy-duty applications?

Do you supply Q&T condition bars?

What sizes are available?

What is the HSN code for alloy steel square bars?

Do you provide test certificates?

Do you export alloy steel square bars?

WhatsApp us