Home > Seamless Pipe > ASTM A333 / ASME SA333

Grades: 1, 3, 6, 7, 8, 9 — Low Temperature Carbon Steel (LTCS) Pipes

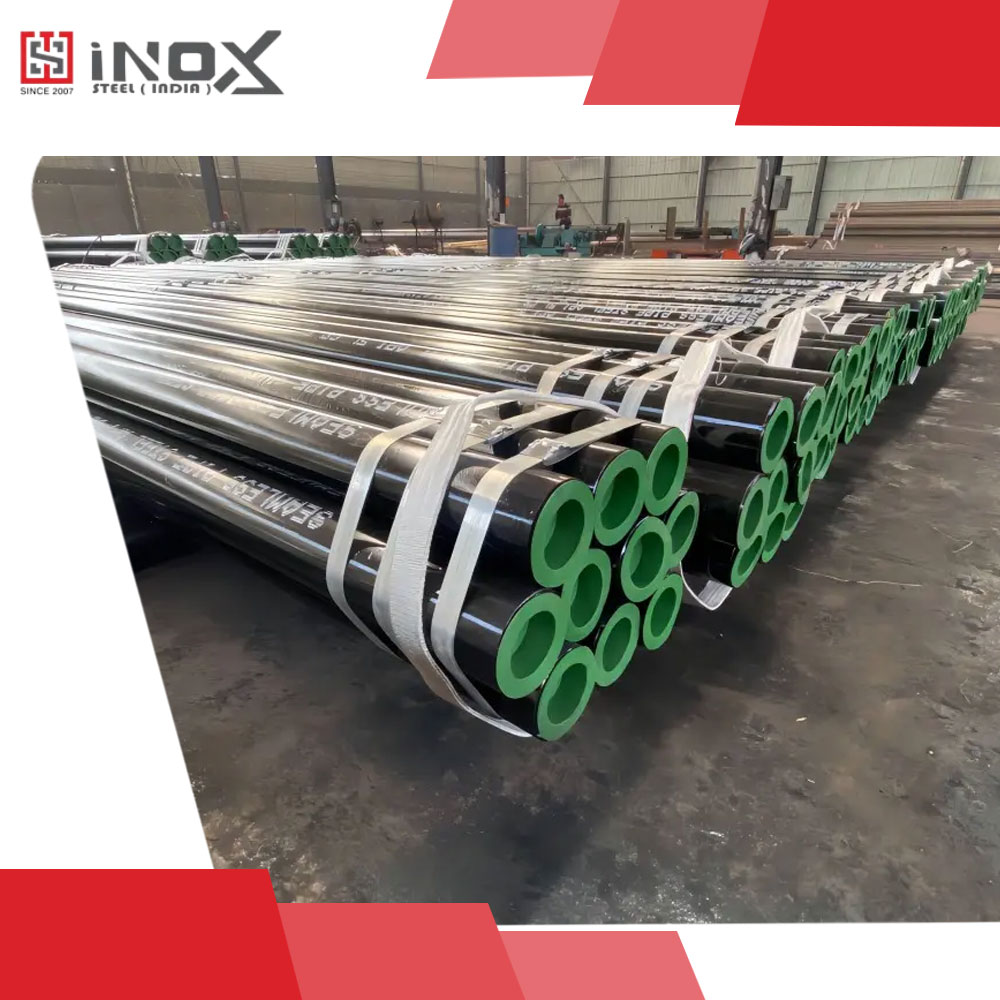

Inox Steel India is one of India’s leading manufacturers, suppliers, and exporters of ASTM A333 / ASME SA333 Low Temperature Carbon Steel (LTCS) Pipes, delivering high-quality seamless pipes designed for extremely low-temperature and cryogenic services. Our LTCS pipes are widely supplied to LNG terminals, gas processing plants, refineries, power plants, petrochemical units, and cryogenic storage facilities across the GCC, Middle East, Africa, Europe, USA, Canada, and South America.

We specialize in supplying the full range of A333 Grades 1–9, including the most widely used Grade 6, and high-performance cryogenic grades such as Grade 7 (0.4–0.7% Ni) and Grade 8 (9% Nickel Steel). These materials are designed to withstand severe temperature drops—ranging from −45°C to −260°C—while maintaining high impact toughness and structural integrity.

Every LTCS pipe manufactured at Inox Steel India undergoes impact testing, hydrostatic testing, ultrasonic inspection, eddy current testing, hardness testing, tensile testing, and full dimensional accuracy checks to ensure compliance with ASTM A333, ASME SA333, IBR (if required), and refinery-grade quality standards.

Our LTCS pipes are extensively used for cryogenic pipelines, LNG handling lines, chilled water systems, low-temperature fluid transport, heat exchangers, and underground low-temp distribution networks, where reliability under rapid thermal contraction and high pressure is crucial.

ASTM A333 (also ASME SA333) is a specification for seamless Low Temperature Carbon Steel pipes designed specifically for cryogenic and sub-zero temperature service.

These pipes are engineered to resist:

Every LTCS pipe from Inox Steel India is built for cryogenic safety, long-term durability, and pressure stability.

| Grade | Min Temperature | Typical Use | Notes |

|---|---|---|---|

| A333 Gr 1 | −45°C | LT fluid lines | General LTCS piping |

| A333 Gr 3 | −100°C | Refrigeration | Better impact values |

| A333 Gr 6 | −45°C | LNG & refineries | Most widely used LTCS grade |

| A333 Gr 7 | −195°C | Cryogenic gas | 0.4–0.7% Ni |

| A333 Gr 8 | −260°C | LNG, LOX, LH2 | 9% Nickel alloy |

| A333 Gr 9 | −75°C | Chilled water & cold boxes | Medium-temp cryogenic service |

| Parameter / Property | Grade 1 | Grade 3 | Grade 6 | Grade 7 | Grade 8 | Grade 9 |

|---|---|---|---|---|---|---|

| Material Type | LTCS | LTCS | LTCS | LTCS | LTCS | LTCS |

| Standard / Spec | ASTM A333 / ASME SA333 | ASTM A333 / ASME SA333 | ASTM A333 / ASME SA333 | ASTM A333 / ASME SA333 | ASTM A333 / ASME SA333 | ASTM A333 / ASME SA333 |

| Service Type | Low Temperature | Low Temperature | Low Temperature | Low Temperature | Low Temperature | Low Temperature |

| Min Temperature | −45°C | −100°C | −45°C | −195°C | −260°C | −75°C |

| Tensile Strength (MPa) | 380 | 450 | 415 | 485 | 520 | 450 |

| Yield Strength (MPa) | 205 | 240 | 240 | 310 | 345 | 275 |

| Elongation (%) | 30 | 28 | 30 | 22 | 20 | 25 |

| Impact Test @ LT | −45°C | −100°C | −45°C | −195°C | −260°C | −75°C |

| Chemical Composition – C | 0.30 Max | 0.19 Max | 0.30 Max | 0.19 Max | 0.13 Max | 0.20 Max |

| Chemical Composition – Mn | 0.40–1.06 | 0.31–0.64 | 0.29–1.06 | 0.40–0.70 | 0.40–0.90 | 0.40–0.70 |

| Chemical Composition – Ni | – | – | – | 0.40–0.70 | 8.40–9.60 | – |

| Manufacturing Method | Seamless | Seamless | Seamless | Seamless | Seamless | Seamless |

| Equivalent Standards | LTCS | LTCS | LTCS | 1% Ni Alloy | 9% Ni Alloy | LTCS |

| Available Sizes | ½″ – 36″ | ½″ – 36″ | ½″ – 36″ | ½″ – 36″ | ½″ – 36″ | ½″ – 36″ |

| Schedules | SCH 20 – XXS | SCH 20 – XXS | SCH 20 – XXS | SCH 20 – XXS | SCH 20 – XXS | SCH 20 – XXS |

| End Finishes | Plain / Bevelled | Plain / Bevelled | Plain / Bevelled | Plain / Bevelled | Plain / Bevelled | Plain / Bevelled |

| Primary Applications | LT service | Cryogenic | LT service | LNG Cryo | LNG / Liquid Gas | Chilled service |

| HSN Code | 7304.19.90 | 7304.19.90 | 7304.19.90 | 7304.19.90 | 7304.19.90 | 7304.19.90 |

| Certifications | EN 10204 3.1 / 3.2 | EN 10204 3.1 / 3.2 | EN 10204 3.1/3.2 | EN 10204 3.1/3.2 | EN 10204 3.1/3.2 | EN 10204 3.1/3.2 |

Temperature Requirements

Each A333 grade corresponds to a minimum operating temperature.

Choose based on cryogenic or low-temp application.

Pressure Rating

Schedules SCH 20 to XXS available depending on pressure.

Nickel Content Requirement

Impact Testing Compliance

Charpy V-Notch values must meet ASTM requirements at actual service temperature.

Certification

We supply LTCS pipes with:

India:

Used extensively in LNG terminals, gas processing units, refineries, cryogenic storage areas.

Middle East:

UAE, Qatar, Saudi Arabia import large volumes for:

Africa:

South Africa, Nigeria, Kenya use LTCS pipes for gas distribution and cooling networks.

Europe & Americas:

LNG terminals, fuel gas handling, petrochemical plants require A333 Grade 6 / Grade 8.

Inox Steel India delivers globally via Mundra, Hazira, JNPT ports.

ASTM A333 / ASME SA333 Low Temperature Carbon Steel (LTCS) Pipes supplied by Inox Steel India are engineered to perform under extremely low temperatures, ranging from −45°C to −260°C, depending on the grade. These pipes offer excellent impact toughness, weldability, and pressure resistance — making them ideal for LNG terminals, cryogenic plants, gas processing units, and cold-temperature fluid lines.

Below are grade-wise applications, dimensional chart, indicative pricing, and QA details in the exact stainless steel page style you prefer.

ASTM A333 Grade 1 — LTCS for General Low Temperature Lines

Service Use:

Low-temperature fluid transportation and refinery piping.

Typical Applications:

Temp Range:

−45°C service

Size Range:

½″ to 36″ NPS (SCH 20 to SCH 160)

Industries:

Chemical | Gas | Refrigeration | Process Plants

ASTM A333 Grade 3 — Sub-Zero Refrigeration Service

Service Use:

Medium cryogenic pipelines requiring higher impact toughness.

Typical Applications:

Temp Range:

−100°C service

Size Range:

½″ – 24″ NPS

Industries:

Food Processing | Refrigeration | Petrochemical

ASTM A333 Grade 6 — MOST WIDELY USED LTCS PIPE

Service Use:

Standard LTCS grade used globally in refineries, LNG, power plants.

Typical Applications:

Temp Range:

−45°C service

Size Range:

½″ – 36″ NPS (SCH 20 to XXS)

Industries:

Oil & Gas | Refineries | Power Plants | LNG

ASTM A333 Grade 7 — Cryogenic Service (Nickel Alloyed)

Service Use:

Cryogenic temperature applications due to nickel content.

Typical Applications:

Temp Range:

−195°C service

(Ni content 0.4–0.7%)

Industries:

LNG | Cryogenic Storage | Steel Plants | Gas Plants

ASTM A333 Grade 8 — Deep Cryogenic (9% Nickel Steel)

Service Use:

Ultra-low temperature pipelines for LNG, LOX, LH2.

Typical Applications:

Temp Range:

−260°C service

Industries:

LNG | Hydrogen | Aerospace | Cryogenic Storage

ASTM A333 Grade 9 — Chilled Water & Partial Cryo

Service Use:

Medium cold-temperature mechanical systems.

Typical Applications:

Temp Range:

−75°C service

Industries:

HVAC | Mechanical | Power Plants

| NPS (Inch) | OD (mm) | Wall Thickness (SCH 40) | Approx. Weight (kg/m) |

|---|---|---|---|

| ½″ | 21.3 | 2.77 | 1.27 |

| 1″ | 33.4 | 3.38 | 2.73 |

| 2″ | 60.3 | 3.91 | 5.44 |

| 3″ | 88.9 | 5.49 | 10.88 |

| 4″ | 114.3 | 6.02 | 14.98 |

| 6″ | 168.3 | 7.11 | 28.26 |

| 8″ | 219.1 | 8.18 | 41.95 |

| 10″ | 273.1 | 9.27 | 62.42 |

| Grade / Standard | Size Range (NPS) | Avg. Price INR/kg (FOB Mumbai) | Approx. USD/kg (FOB India) | Typical Use |

|---|---|---|---|---|

| A333 Gr 1 | ½″–36″ | ₹ 110 – ₹ 135 | $1.55 – $1.95 | LTCS pipelines |

| A333 Gr 3 | ½″–24″ | ₹ 150 – ₹ 185 | $2.10 – $2.60 | Sub-zero cooling |

| A333 Gr 6 (MOST USED) | ½″–36″ | ₹ 135 – ₹ 170 | $1.90 – $2.35 | LNG, Refineries |

| A333 Gr 7 | ½″–16″ | ₹ 260 – ₹ 325 | $3.30 – $4.00 | Cryogenic (-195°C) |

| A333 Gr 8 (9% Ni) | ½″–16″ | ₹ 380 – ₹ 520 | $5.10 – $7.00 | LNG (-260°C) |

| A333 Gr 9 | ½″–24″ | ₹ 155 – ₹ 185 | $2.30 – $2.60 | Chilled water |

✔ HSN 7304.19.90 — LTCS Seamless Carbon Steel Pipes

(All grades 1–9)

Every LTCS pipe undergoes rigorous quality checks to ensure suitability for low-temperature environments.

Quality Tests Conducted:

Documentation Supplied:

Inox Steel India is a trusted global supplier of Low Temperature Carbon Steel (LTCS) ASTM A333 / ASME SA333 Pipes, serving LNG terminals, refineries, gas processing plants, power plants, and cryogenic industries worldwide.

Our expertise in A333 Grades 1–9, especially Grade 6 and Grade 8, makes us a preferred partner for highly sensitive low-temperature and cryogenic piping systems.

Core Advantages of Inox Steel India:

Inox Steel India ensures reliability and safety in every low-temperature and cryogenic piping system.

| Industry | Application | Preferred Grades |

|---|---|---|

| LNG Terminals | LNG transfer, vapour return | Gr 6 / Gr 7 / Gr 8 |

| Cryogenic Plants | LOX, LN2, LH2 transport lines | Gr 7 / Gr 8 |

| Refineries | Low-temperature hydrocarbon service | Gr 6 |

| Gas Processing Units | Gas chilling, separation units | Gr 6 / Gr 9 |

| Power Plants | Chilled water, cold boxes | Gr 6 / Gr 9 |

| Petrochemical Units | Sub-zero process lines | Gr 6 / Gr 3 |

| Marine & Offshore | Cryogenic cargo systems | Gr 8 |

| EPC Projects | LTCS pipeline fabrication | Gr 6 |

To ensure safe transportation and zero damage during export, all LTCS pipes from Inox Steel India follow strict international packing standards:

🌍 Major Export Destinations:

UAE • Saudi Arabia • Qatar • Oman • Kuwait • Egypt • South Africa • USA • Canada • Mexico • Brazil • Germany • Italy • South Korea • Malaysia

If you are searching for a Low Temperature Carbon Steel (LTCS) ASTM A333 pipe supplier near Alankar Cinema, Mumbai, Inox Steel India is your most reliable source.

We offer:

Trusted by EPCs, cryogenic installers, LNG contractors & industrial users.

Need help choosing the right LTCS grade?

Get expert-grade selection, MTC samples, and quotations within 24 hours.

📥 Downloads Available:

Datasheet • Price List • Impact Test Charts • LNG Service Certification (PDF)

52-A, Mulji Thackersi Bldg, Islampura Street, Shop No. 10, Near Alankar Cinema, Mumbai – 400 004

alloy@inoxsteelindia.in

+91 9930796690

Inox Steel India

Email

Phone

ASTM A333 is specifically designed for low-temperature and cryogenic applications, suitable for temperatures from −45°C to −260°C.

Grade 6 is the most widely used LTCS material globally.

Yes — Grade 7 and Grade 8 are specifically designed for cryogenic LNG lines.

HSN Code: 7304.19.90

Yes — on request, with complete IBR documentation.

Yes — regular exports to GCC, Africa, Europe & North America.

Yes — mandatory for all LTCS grades.

Inox Steel India supplies premium-quality ASTM A53 Grade A & Grade B Seamless, ERW & GI Pipes, suitable for structural, water, mechanical, and low-pressure service.

If your project requires reliable performance, quality testing, and competitive pricing — we are ready to serve.

WhatsApp us