Home > Welded Pipes > ASTM A53 / SA53

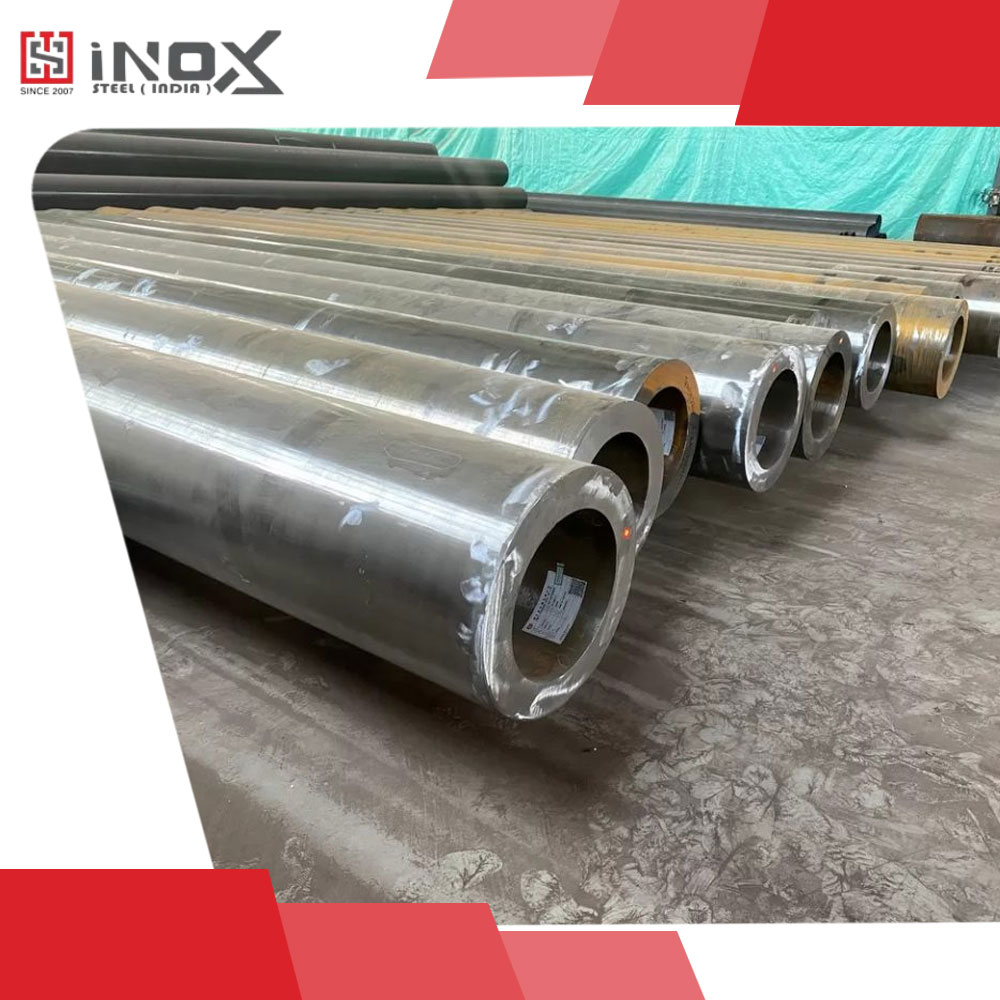

Inox Steel India is a leading manufacturer and global supplier of ASTM A53 / ASME SA53 Carbon Steel ERW & EFW Pipes, available in both Grade A and Grade B, suitable for water lines, oil & gas transmission, structural applications, low-pressure steam, compressed air, mechanical systems, and general engineering use.

ASTM A53 is one of the most widely used carbon steel pipe standards worldwide. Inox Steel India manufactures Type E (ERW) and Type S (EFW) welded pipes in various coatings including black, bare, painted, and hot-dip galvanized, depending on service environment.

Our A53 ERW/EFW pipes are supplied to petrochemical plants, refineries, power plants, construction companies, HVAC manufacturers, fire-fighting contractors, and mechanical fabrication units across India, Middle East, Africa, Europe, and the USA.

ASTM A53 defines welded & seamless carbon steel pipes for general-purpose and pressure applications.

It is the most commonly used CS pipe standard for:

| Grade | Characteristics |

|---|---|

| A53 Grade A | Lower strength, easier to bend/form, used for general applications |

| A53 Grade B | Higher strength, used in oil, gas, steam & pressure applications |

Inox Steel India primarily supplies Type E (ERW) and Type S (EFW) as per industry demand.

✔ ERW Carbon Steel Pipes (Type E)

✔ EFW Carbon Steel Pipes (Type S)

✔ Black Steel Pipes

Uncoated carbon steel pipes used for structural and welding applications.

✔ Galvanized Steel Pipes (GI Pipes)

Zinc-coated pipes for corrosion protection in water lines & outdoor installations.

1️⃣ Raw Material Inspection

Hot rolled coils or plates tested for chemical composition & surface quality.

2️⃣ Forming & Rolling

Metal formed into a cylindrical shape with controlled dimensions.

3️⃣ Welding Process

Welds inspected visually and through NDT.

4️⃣ Heat Treatment (Optional)

Normalizing is done for enhanced strength and uniformity (as per customer requirement).

5️⃣ Galvanizing (Optional)

Hot dip zinc coating applied for corrosion resistance.

6️⃣ Hydrostatic Testing

Mandatory pressure test as per ASTM A53.

7️⃣ Eddy Current Testing

Required for ERW pipes to check weld integrity.

8️⃣ Threading (Optional)

BSP / NPT threading along with couplings for plumbing & fire-fighting applications.

9️⃣ Final Finishing & Marking

Grade, Type, Heat Number, OD & WT printed as per SA53.

Water Transport & Plumbing

Galvanized A53 pipes widely used for water supply lines.

Oil & Gas (Low/Medium Pressure)

Used in process piping, transmission lines, and utility systems.

Fire-Fighting & HVAC

Preferred for fire hydrants, sprinklers, and chilled/hot water systems.

Air & Steam Lines

ERW/EFW pipes used in compressed air and low-pressure steam service.

Construction & Fabrication

Used in scaffolding, fencing, frames, and structural assemblies.

Automotive & Mechanical Industry

Used for mechanical structures, conveyors, fabrication works.

General Industrial Use

A53 pipes are used across engineering, fabrication, EPC, maintenance & utility applications.

ASTM A53 / SA53 is one of the world’s most widely used carbon steel pipe standards for water transportation, structural purposes, mechanical systems, utility lines, fire-fighting networks, fabrications, and low/medium-pressure oil & gas lines.

A53 pipes are available as:

✔ Type E — ERW (Electric Resistance Welded)

Most common type for water lines, air lines, structural use.

✔ Type S — EFW (Electric Fusion Welded)

Used for higher integrity weld requirements.

✔ Grade A & Grade B

Inox Steel India supplies both grades in black, painted, and hot-dip galvanized variants depending on environmental conditions and customer specifications.

| Parameter / Property | ASTM A53 Grade A | ASTM A53 Grade B | Standard Requirements – ASTM A53 / SA53 (ERW/EFW) |

|---|---|---|---|

| Material Type | Carbon Steel | Carbon Steel (Higher Strength) | Carbon Steel ERW / EFW Pipes |

| Manufacturing Standard | ASTM A53 / ASME SA53 | ASTM A53 / ASME SA53 | ERW / EFW / Seamless |

| Pipe Types | Type E (ERW), Type F, Type S | Type E (ERW), Type S | Specifies pipe type & testing |

| Grade Strength | Lower strength | Higher strength | Mechanical limits per ASTM |

| Yield Strength (YS) | 205 MPa | 240 MPa | Defined in ASTM |

| Tensile Strength (TS) | 330 MPa | 415 MPa | Defined in ASTM |

| Weld Type | ERW / EFW | ERW / EFW | Fusion-welded or resistance-welded |

| Coating Options | Bare / Galvanized | Bare / Galvanized | Zinc coat per ASTM A53 spec |

| Corrosion Resistance | Moderate | Moderate | Can be galvanized for improved performance |

| Hydrostatic Test | Required | Required | Mandatory |

| NDT Requirements | Eddy Current (ERW) | Eddy Current (ERW) | As per ASTM |

| Heat Treatment | Not always required | Not always required | Furnace weld normalizing optional |

| Chemical Composition | Lower carbon | Higher carbon | Defined range in ASTM A53 |

| OD Range | ½” – 24” | ½” – 24” | As per manufacturing capability |

| Wall Thickness | SCH 10 – SCH 160 | SCH 10 – SCH 160 | Standard schedules |

| End Types | Plain / Bevelled / Threaded | Plain / Bevelled / Threaded | BSP/NPT threads available |

| Surface Condition | Black, Bare, Painted, Galvanized | Black, Bare, Painted, Galvanized | ASTM-compliant |

| Typical Applications | Water lines, structural, low-pressure | Oil, gas, steam, compressed air | General & low-pressure service |

| Testing Documents | MTC 3.1, Hydro, NDT | MTC 3.1, Hydro, NDT | Required |

| HSN Code | 7306.30 | 7306.30 | CS welded pipes |

✔ A53 Grade A

✔ A53 Grade B

✔ Black / Bare Pipes

General-purpose use, fabrication, welding & mechanical applications.

✔ Paint-Coated Pipes

Anti-rust oil or epoxy coating for extended life.

✔ Hot-Dip Galvanized (GI) Pipes

Zinc-coated for water supply, outdoor use & corrosion-prone areas.

✔ Varnish / Lacquer Coated

For long-term storage and protection.

✔ For water supply, plumbing & GI networks

→ Galvanized A53 ERW Pipes

✔ For oil, gas, steam, compressed air

→ A53 Grade B ERW/EFW Pipes

✔ For structural & fabrication use

→ A53 Grade A ERW Pipes

✔ For corrosive environments

→ Hot-dip galvanized

✔ For threaded pipe systems

→ Use Type E (ERW) with BSP/NPT threading

| Parameter | Capability |

|---|---|

| Outside Diameter (OD) | ½” – 24” |

| Wall Thickness | SCH 10 – SCH 160 |

| Length | 6 m / 12 m / Custom |

| Ends | Plain Ends / Bevelled Ends / Threaded with Couplings |

| Coatings | Bare, Black, Painted, GI |

| Form | Round |

| Variant | Price (INR/kg) | Price (USD/kg) |

|---|---|---|

| A53 Grade A ERW Pipes | ₹ 62 – ₹ 78 | $ 0.85 – $ 1.10 |

| A53 Grade B ERW Pipes | ₹ 65 – ₹ 85 | $ 0.90 – $ 1.20 |

| A53 Grade B EFW Pipes | ₹ 75 – ₹ 105 | $ 1.10 – $ 1.45 |

| Galvanized A53 Pipes | +₹ 12 – ₹ 22 (coating) | +$ 0.15 – $ 0.30 |

| Threaded A53 Pipes | Custom | Custom |

Prices vary by OD, thickness, grade, welding type, and GI coating thickness.

7306.30 — Carbon Steel Welded Pipes

✔ Mandatory Tests (ASTM A53 Standard)

✔ Optional Tests (On Request)

✔ Coating Tests (for GI pipes)

✔ Documents Provided

✔ Third-Party Inspections (TPI Available)

SGS • BV • TÜV • DNV • Lloyd’s

Inox Steel India exports ASTM A53 ERW/EFW pipes to:

Middle East:

Africa:

Europe:

Americas:

Asia Pacific:

Used extensively in plumbing, fire-fighting, mechanical fabrication, utility pipelines, civil construction, oil & gas networks, and general engineering.

Inox Steel India is a trusted manufacturer and exporter of ASTM A53 / SA53 ERW & EFW Carbon Steel Pipes, supplying to EPC contractors, fire-fighting system integrators, plumbing contractors, construction firms, mechanical fabrication units, oil & gas utility pipelines, and infrastructure developers.

Our CS pipes are recognized for:

Inox Steel India ensures reliable supply, stable quality, and competitive pricing — making it a preferred source for ASTM A53 pipes worldwide.

Water Supply & Plumbing

A53 GI and ERW pipes are standard for potable water systems, cold/hot water lines, and plumbing networks.

Fire-Fighting Systems

Used in fire hydrant systems, sprinkler lines, risers & wet/dry fire pipes.

HVAC & Mechanical Systems

Used for chilled/hot water pipelines, compressed air lines & mechanical ducting supports.

Oil & Gas (Low/Medium Pressure)

Utility lines, small process lines, gas distribution networks.

Civil & Infrastructure Projects

Bridges, sheds, buildings, scaffolding, trusses, columns & structural fabrication.

Automotive & Engineering

Machinery parts, supports, frames, conveyor systems.

Industrial Fabrication

Fencing, gates, equipment frames, general assemblies.

✔ Standard Packing

✔ Export Packing (Seaworthy)

✔ Additional Options

✔ Ports of Dispatch

JNPT • Mundra • Hazira • Chennai

Looking for ASTM A53 / SA53 ERW & EFW Carbon Steel Pipes for water supply, fire-fighting, structural, HVAC, fabrication or oil & gas applications?

52-A, Mulji Thackersi Bldg, Islampura Street, Shop No. 10, Near Alankar Cinema, Mumbai – 400 004

alloy@inoxsteelindia.in

+91 9930796690

Inox Steel India

Email

Phone

→ Grade A = lower strength, easier forming

→ Grade B = higher strength, used in oil/gas/steam applications

Yes. ERW A53 pipes can be supplied with BSP/NPT threads + couplings.

Yes — GI coating is available as per ASTM & IS standards.

Water lines, fire-fighting, structural fabrication, HVAC, compressed air, low-pressure oil & gas.

Yes — EN 10204 3.1, hydro test reports, EC test reports.

Up to 24 inches.

Get technical support, the best prices, and fast delivery.

WhatsApp us