Home > Seamless Pipe > Copper Nickel & Brass Pipe

Cu-Ni 90/10 • Cu-Ni 70/30 • Brass C26000 | ASTM B111 / B135 / B43

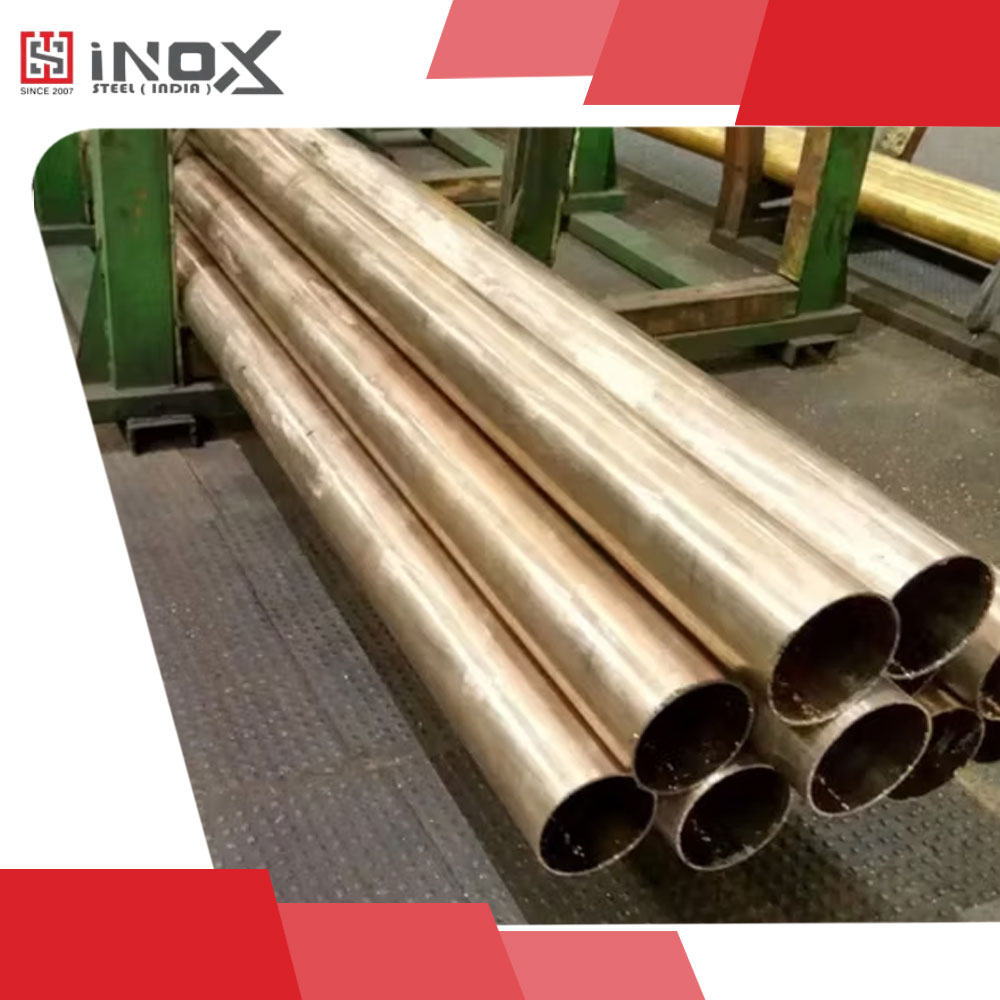

Inox Steel India is one of the leading manufacturers, suppliers, and exporters of Copper Nickel (Cu-Ni) and Brass Pipes in India, supplying to marine, offshore, desalination, HVAC, power, chemical, and heat exchanger industries across the GCC, Middle East, African nations, European countries, and North & South America.

We specialize in high-performance non-ferrous piping materials — Copper Nickel 90/10 (UNS C70600), Copper Nickel 70/30 (UNS C71500) and Brass C26000/C27000/C28000 — conforming to ASTM B111, ASTM B135, and ASTM B43 standards.

With ISO, IBR, PED, and Third-Party inspection compliance, every pipe manufactured at Inox Steel India undergoes precision extrusion, controlled annealing, dimensional calibration, and corrosion testing to ensure excellent seawater compatibility, mechanical strength, and long service life in harsh marine and industrial environments.

Our Cu-Ni and Brass Pipes are widely used in shipbuilding, condensers, heat exchangers, desalination plants, offshore platforms, seawater cooling lines, power plants, chemical processing units, and engineered systems demanding anti-fouling, high corrosion resistance, and thermal conductivity.

Copper Nickel (Cu-Ni) Pipes are premium non-ferrous pipes known for their:

Cu-Ni 90/10 (C70600)

→ Ideal for marine cooling, offshore lines, and heat exchangers

Cu-Ni 70/30 (C71500)

→ Higher strength + superior corrosion resistance, used in aggressive seawater & brine

Brass Pipes (C26000 / C27000 / C28000) offer:

We supply Copper Nickel & Brass Pipes in the following engineering grades:

| Material | UNS | Standard |

|---|---|---|

| Copper Nickel 90/10 | C70600 | ASTM B111 / ASME SB111 |

| Copper Nickel 70/30 | C71500 | ASTM B111 / ASME SB111 |

| Brass 70/30 | C26000 | ASTM B135 / B43 |

| Brass 63/37 | C27200 / C28000 | ASTM B135 / B43 |

ASTM B111 / ASME SB111 – Cu-Ni 90/10 (C70600), Cu-Ni 70/30 (C71500)

| Parameter / Property | Copper Nickel 90/10 (C70600) | Copper Nickel 70/30 (C71500) |

|---|---|---|

| Material Type | Copper-Nickel Alloy | Copper-Nickel Alloy |

| UNS Number | C70600 | C71500 |

| Standard / Specification | ASTM B111 / ASME SB111 | ASTM B111 / ASME SB111 |

| Material Class | Cu-Ni 90/10 (10% Nickel) | Cu-Ni 70/30 (30% Nickel) |

| Corrosion Resistance | Excellent in seawater | Superior in strong seawater & brine |

| Temperature Service | Up to 300°C | Up to 350°C |

| Tensile Strength (MPa) | 275–345 | 380–485 |

| Yield Strength (MPa) | 105–130 | 130–180 |

| Elongation (%) | 30–45 | 30–40 |

| Hardness (HB) | 60–90 | 80–110 |

| Erosion Resistance | High | Very High |

| Chemical Composition (%) | Cu 88.7–90.2, Ni 9–11, Fe 1–1.8, Mn 1 Max | Cu 66.3–68.5, Ni 29–33, Fe 0.4–1.0 |

| Heat Treatment | Annealed / Stress Relieved | Annealed / Stress Relieved |

| Manufacturing Method | Seamless / Welded | Seamless / Welded |

| Equivalent EN / DIN Grades | CW352H (CuNi10Fe1Mn) | CW354H (CuNi30Mn1Fe) |

| Available Sizes (OD) | 6 – 254 mm | 6 – 254 mm |

| Schedules (WT) | SCH 5 to SCH 80 | SCH 5 to SCH 80 |

| Application Areas | Marine, Shipbuilding, Desalination | Offshore, Heat Exchangers, Subsea |

| End Finishes | Plain / Bevelled | Plain / Bevelled |

| Testing Requirements | Eddy Current, Hydro, UT, PMI | Eddy Current, Hydro, UT, PMI |

| HS Code / HSN Code | 7411.10.00 | 7411.10.00 |

| Certifications | EN 10204 3.1, IBR, Third Party | EN 10204 3.1, IBR, Third Party |

BRASS PIPE (C26000 / C27000 / C28000)

| Parameter | Brass (C26000 – 70/30 Brass) |

|---|---|

| Material Type | Brass Alloy (Copper-Zinc) |

| UNS Number | C26000 |

| Standard | ASTM B135 / B43 |

| Tensile Strength | 315–350 MPa |

| Yield Strength | 95–130 MPa |

| Elongation | 25–40% |

| Temp Resistance | Up to 250°C |

| Applications | Heat exchangers, fittings, general purpose |

| Composition | Cu 68.5–71.5, Zn Balance |

| HSN Code | 7411.21.00 |

Choosing the correct Duplex/Super Duplex grade depends on:

Operating Environment

Pressure & Temperature Ratings

ASTM B111 pipes are suitable for high-pressure seawater, condensers, heat exchangers, and oil & gas cooling systems.

Corrosion Resistance Requirements

Anti-Biofouling Behavior

Cu-Ni alloys naturally resist marine growth → lower maintenance, zero coatings required.

Thermal Conductivity

Brass & Cu-Ni provide excellent thermal performance → perfect for condensers & chillers.

Certifications Needed

IBR • PED • EN 10204 3.1/3.2 • Third-party inspection (SGS, BV, TUV)

India:

Major demand in Mumbai, Cochin, Vishakhapatnam shipyards, HVAC contractors, and chemical plants.

Middle East:

Saudi Arabia, UAE, Oman, and Qatar use Cu-Ni 90/10 & 70/30 extensively in:

Africa:

Egypt, Nigeria, Angola prefer Cu-Ni for offshore & marine cooling.

Europe & Americas:

UK, Italy, Germany, USA, Brazil use Copper Nickel & Brass tubes for industrial heat exchangers and marine engineering.

Inox Steel India supports global shipments via JNPT, Mundra, Hazira, ensuring timely delivery and certified material readiness.

Copper Nickel & Brass Pipes from Inox Steel India are engineered for superior performance in seawater, thermal systems, heat exchangers, and industrial cooling applications. Their inherent corrosion resistance, anti-fouling behaviour, and thermal conductivity make them indispensable in marine and industrial environments.

Below is the grade-wise application mapping, dimensional capabilities, and selection reference — written exactly like your stainless steel example.

Copper Nickel 90/10 (C70600) – ASTM B111 / ASME SB111

Service Use:

Marine cooling, seawater handling, low–medium velocity flow lines.

Typical Applications:

Size Range:

½″ – 24″ NB (SCH 5 to SCH 80)

Temperature Range:

Up to ~300°C

Industry Sectors:

Marine | Shipbuilding | Power | HVAC | Desalination | Chemical

Copper Nickel 70/30 (C71500) – ASTM B111 / ASME SB111

Service Use:

High-velocity seawater, brine, severe marine corrosion environments.

Typical Applications:

Size Range:

½″ – 24″ NB, extended to 254 mm OD for tubes

Temperature Range:

Up to ~350°C

Industry Sectors:

Offshore Oil & Gas | Marine | Power | Chemical | Desalination

Brass Pipe (C26000 / C27000 / C28000) – ASTM B135 / B43

Service Use:

General industrial use, heat transfer, plumbing, forming applications.

Typical Applications:

Size Range:

¼″ – 8″ in OD (hard/half-hard/soft temper)

Temperature Range:

Up to 250°C

Industry Sectors:

HVAC | Plumbing | Heat Exchangers | General Engineering

| NPS (Inch) | OD (mm) | Wall Thickness (Typical) | Approx. Weight (kg/m) |

|---|---|---|---|

| ½″ | 15.88 | 1.20 – 2.0 | 0.55 |

| 1″ | 22.22 | 1.50 – 2.5 | 0.95 |

| 1½″ | 38.10 | 1.65 – 3.0 | 1.90 |

| 2″ | 50.80 | 2.00 – 3.5 | 3.10 |

| 3″ | 76.20 | 2.50 – 4.0 | 5.75 |

| 4″ | 101.60 | 3.00 – 4.5 | 8.90 |

| 6″ | 152.40 | 3.50 – 5.0 | 16.40 |

| 8″ | 203.20 | 4.00 – 6.0 | 28.30 |

| Grade / Standard | Size Range (OD) | Avg. Price INR/kg (FOB Mumbai) | Approx. USD/kg (FOB India) | Typical Use |

|---|---|---|---|---|

| Cu-Ni 90/10 (C70600 – ASTM B111) | 6 – 254 mm | ₹ 870 – ₹ 1,100 | $ 10.50 – $ 13.20 | Marine, condensers, HVAC |

| Cu-Ni 70/30 (C71500 – ASTM B111) | 6 – 254 mm | ₹ 1,050 – ₹ 1,450 | $ 13.00 – $ 17.00 | Offshore & aggressive seawater |

| Brass C26000 (ASTM B135/B43) | 6 – 203 mm | ₹ 540 – ₹ 700 | $ 6.50 – $ 8.30 | Heat exchangers, HVAC |

🧾 Actual price depends on temper (soft / hard), wall thickness, origin, and finish

These codes apply to seamless, welded, and annealed non-ferrous pipes under global customs regulations

Every Copper Nickel and Brass pipe supplied by Inox Steel India is subjected to rigorous quality control as per ASTM and international marine standards.

Quality Tests Conducted:

Documentation Supplied:

This ensures all products meet the stringent requirements for marine, offshore, thermal, and industrial service.

At Inox Steel India, we provide engineering-grade Copper Nickel and Brass Pipes designed for marine, thermal, HVAC, and industrial applications requiring long-term corrosion resistance and high thermal conductivity.

Key Benefits Our Clients Depend On:

Inox Steel India focuses on long-term reliability, not just supply.

| Industry | Application | Recommended Grade |

|---|---|---|

| Marine & Shipbuilding | Cooling loops, ballast lines, firefighting | Cu-Ni 90/10 |

| Offshore Platforms | High-velocity seawater systems | Cu-Ni 70/30 |

| Desalination Plants | RO feed lines, intake/outfall | Cu-Ni 70/30 |

| HVAC & Chillers | Coils, heat exchanger tubes | Brass C26000 |

| Power Plants | Condensers, evaporators | Cu-Ni 90/10 / 70/30 |

| Chemical Processing | Low-corrosion process tubing | Brass / Cu-Ni 90/10 |

| Heat Exchangers | Thermal transfer pipes | Brass & Cu-Ni |

| Oil & Gas | Seawater cooling & firewater lines | Cu-Ni 70/30 |

All Copper Nickel & Brass Pipes from Inox Steel India are export-packed as per marine and international shipping standards:

Common Export Destinations:

UAE • Saudi Arabia • Qatar • Oman • Kuwait • Bahrain • Egypt • Nigeria • South Africa • Italy • Germany • UK • USA • Brazil • Mexico

Buyers searching for a Copper Nickel & Brass Pipe supplier near Alankar Cinema, Mumbai trust Inox Steel India for:

Our location and manufacturing excellence make us one of the most preferred suppliers in India and internationally.

Our technical sales team responds within 24 hours with:

✔ Grade selection assistance

✔ Pricing (INR + USD)

✔ Stock readiness

✔ Documentation (3.1 / 3.2)

✔ Delivery timeline

📥 Download: Product Catalog • Price List 2025 • Schedule Chart (Coming Soon)

52-A, Mulji Thackersi Bldg, Islampura Street, Shop No. 10, Near Alankar Cinema, Mumbai – 400 004

alloy@inoxsteelindia.in

+91 9930796690

Inox Steel India

Email

Phone

Cu-Ni pipes are used in seawater cooling, condensers, heat exchangers, offshore platforms, and marine systems due to their exceptional resistance to corrosion and biofouling.

Cu-Ni 90/10 → Standard seawater, HVAC, shipbuilding

Cu-Ni 70/30 → High-velocity seawater, aggressive marine/brine environments

ASTM B111 / ASME SB111 covers Cu-Ni seamless & welded pipes.

Brass performs well in general industrial & heat exchanger applications but Cu-Ni is always preferred for seawater.

HSN Code: 7411.10.00

Yes — all tempers are available depending on application need.

Yes — regular exports to UAE, Saudi Arabia, Oman, Qatar, Europe, USA, and Africa.

Yes — SGS, BV, TÜV, DNV, and Lloyd’s inspection is available on request.

At Inox Steel India, every Cu-Ni & Brass pipe is manufactured with precision, corrosion resistance, and global compliance.

Whether your requirement is for marine cooling, HVAC coils, heat exchangers, or desalination, we deliver ASTM B111 / B135 / B43–compliant pipes that ensure long, maintenance-free service.

WhatsApp us