Home > Square Bars > Titanium Seamless Tubes

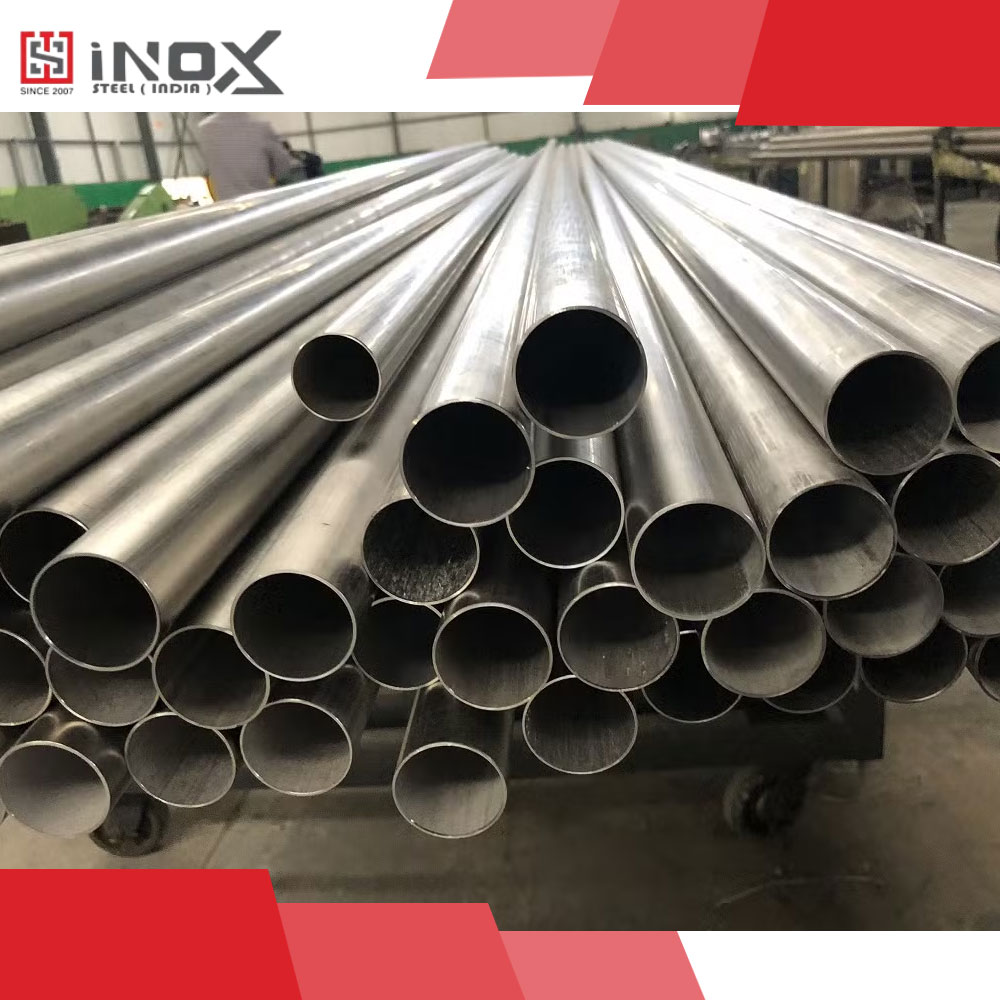

Inox Steel India supplies premium-quality Titanium Seamless Tubes engineered for industries where a combination of extreme strength, low weight, corrosion resistance and thermal stability is mandatory.

Manufactured in full compliance with ASTM B338, these tubes deliver reliable performance in aerospace systems, power plant heat exchangers, marine components, chemical processing loops, desalination units and high-performance engineering applications.

Titanium alloys are globally recognized for their exceptional strength-to-weight ratio, making them significantly stronger than stainless steel while being nearly 40% lighter.

Titanium forms a protective oxide layer that provides remarkable resistance to chlorides, seawater, acids, oxidizing environments, and high-temperature conditions.

This makes titanium seamless tubes the preferred choice for aggressive or high-pressure environments.

Each tube undergoes precision extrusion, cold drawing, annealing, solution processing and strict testing to ensure perfect dimensional accuracy, mechanical stability, and clean internal surfaces suitable for fluid transfer, heat exchange and pressure systems.

Inox Steel India supplies titanium seamless tubes to advanced engineering sectors across India, GCC, Europe, USA, Africa & Southeast Asia.

Titanium alloys are chosen for their unmatched strength-to-weight ratio, corrosion resistance, thermal stability and biocompatibility.

These characteristics make ASTM B338 titanium seamless tubes ideal for critical service environments.

Recommended Grades: Gr 5 · Gr 9

Best Grades: Gr 2 · Gr 12

Recommended: Gr 2 · Gr 12

| Application | Recommended Grade | Why |

| High corrosion chemical service | Gr 2 / Gr 12 | Excellent acid & brine resistance |

| Marine & seawater systems | Gr 2 / Gr 12 | No pitting or biofouling |

| Aerospace & high strength | Gr 5 | Highest strength-to-weight ratio |

| Coiled tubing | Gr 9 | Flexible with good strength |

| Heat exchangers | Gr 2 | Thermal + corrosion balance |

| Grade | OD Range | WT Range | Typical Use |

| Gr 2 | 6 – 219 mm | 0.5 – 8 mm | Heat exchangers, chemical lines |

| Gr 5 | 8 – 89 mm | 1 – 10 mm | Aerospace & automotive |

| Gr 9 | 3 – 50 mm | 0.4 – 4 mm | Coiled tubing |

| Gr 12 | 6 – 89 mm | 1 – 8 mm | Marine & brine systems |

| Grade | Price Range (₹/kg) | Notes |

| Gr 2 | ₹2,400 – ₹3,500 | Most widely used |

| Gr 5 | ₹3,800 – ₹6,000 | Aerospace-grade |

| Gr 9 | ₹3,500 – ₹5,500 | Coiled tubing |

| Gr 12 | ₹3,200 – ₹4,800 | Chemical & seawater |

Grade 2 is preferred due to its excellent corrosion resistance and thermal stability. Yes — Titanium is one of the best materials for warm seawater and high-chloride environments. Gr 5 is stronger (aerospace-grade), while Gr 9 is more formable and ideal for coiled tubing. Yes — Gr 5 and Gr 9 tubes are used in racing & performance exhaust systems. MTC 3.1, PMI report, mechanical tests, NDT/UT reports, heat treatment chart. Which titanium grade is best for heat exchangers?

Is titanium suitable for seawater cooling systems?

What is the difference between Grade 5 and Grade 9 tubes?

Can titanium tubes be used for automotive exhaust systems?

What certification is provided?

WhatsApp us