Grades: D2, H11, H13 | Supplier & Exporter

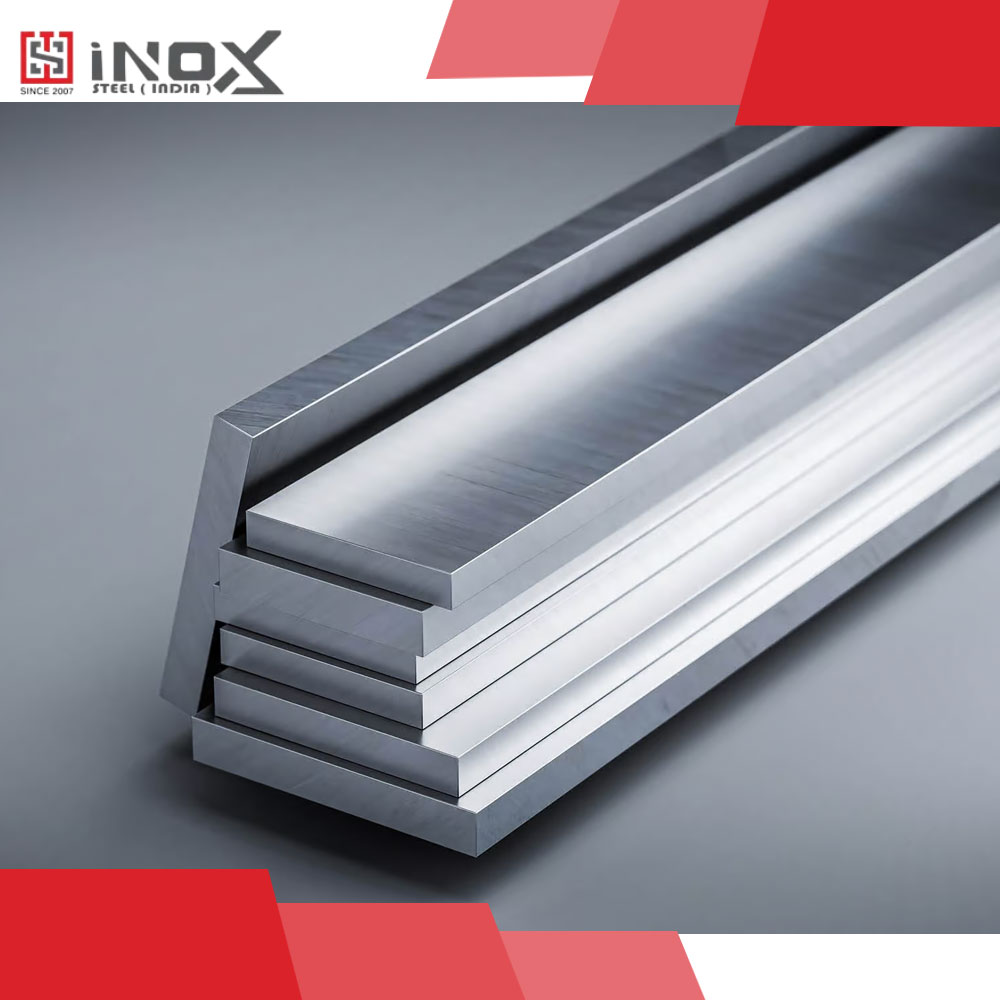

Inox Steel India is a trusted manufacturer, supplier, and exporter of tool steel flat bars in India, offering premium-quality D2, H11, and H13 flat bars for critical tooling and high-performance applications.

Our tool steel flat bars are produced from carefully alloyed tool steels using controlled hot rolling and forging processes, followed by annealing to ensure uniform structure and machinability. These flat bars are engineered to deliver high hardness, excellent wear resistance, thermal stability, and long tool life, making them ideal for dies, molds, cutting tools, and hot-work applications.

Buyers searching for tool steel flat bars, tool steel flat bar for sale, steel flat bar near me, or wanting to understand what is flat bar steel used for in tooling rely on Inox Steel India for certified material, consistent quality, and dependable supply from Mumbai.

A tool steel flat bar is a solid rectangular bar manufactured from high-alloy tool steel, designed specifically for tooling, cutting, forming, and hot-working operations. Unlike mild or alloy steel flat bars, tool steels are formulated to achieve very high hardness after heat treatment, while maintaining resistance to wear, deformation, and thermal fatigue.

Tool steel flat bars are commonly used where components must retain sharp edges, resist abrasion, or withstand repeated heating and cooling cycles.

These properties make tool steel flat bars essential in tool rooms, forging units, die casting plants, and heavy manufacturing facilities.

High-carbon, high-chromium cold-work tool steel offering exceptional wear resistance and edge retention. Commonly used for shear blades, punches, blanking dies, and cutting tools.

Hot-work tool steel with good toughness and resistance to thermal shock, suitable for forging dies, extrusion tools, and hot punches.

Premium hot-work tool steel with excellent hot hardness, thermal fatigue resistance, and toughness, widely used for die casting dies, hot forging dies, and plastic molds.

Inox Steel India supports buyers with grade selection based on operating temperature, impact load, wear requirement, and heat-treatment process.

In India, tool steel flat bars see strong demand in Mumbai, Pune, Ahmedabad, Chennai, Coimbatore, and Bengaluru, driven by tool rooms, automotive OEMs, forging industries, and die casting units.

Globally, D2 and H13 flat bars are exported to GCC countries, Africa, Europe, and North America, where precision tooling and long tool life are critical for manufacturing efficiency.

With dispatch from JNPT (Mumbai), Mundra, and Hazira ports, Inox Steel India ensures timely delivery, export-compliant packaging, and complete traceability.

| Industry Segment | Typical Applications |

| Tool & Die Industry | Punches, dies, shear blades |

| Forging Industry | Hot forging dies, mandrels |

| Die Casting | Aluminum & zinc die casting dies |

| Automotive | Press tools, trimming dies |

| Plastic Molding | Injection molds, core plates |

| Heavy Engineering | Cutting tools, wear plates |

Grade-wise application guidance:

D2 Tool Steel Flat Bars → Cold-work dies, punches, shear blades, cutting tools

H11 Tool Steel Flat Bars → Hot punches, extrusion dies, forging tools

H13 Tool Steel Flat Bars → Die casting dies, hot forging dies, plastic molds

Inox Steel India supplies tool steel flat bars in standard stock sizes and custom machined dimensions to suit tooling requirements.

Standard Size Range:

Common Commercial Sizes (mm):

25×6 | 40×8 | 50×10 | 65×12 | 75×16 | 100×20

| Size (mm) | Approx. Weight (kg/m) |

| 25 × 6 | 1.18 |

| 40 × 8 | 2.51 |

| 50 × 10 | 3.93 |

| 65 × 12 | 6.12 |

| 75 × 16 | 9.42 |

| 100 × 20 | 15.70 |

| Grade | Price INR / Kg |

| D2 Tool Steel Flat Bar | ₹220 – ₹320 |

| H11 Tool Steel Flat Bar | ₹180 – ₹260 |

| H13 Tool Steel Flat Bar | ₹200 – ₹300 |

Prices are Ex-Mumbai / Ex-Works India and subject to alloy surcharge and heat treatment requirements.

HSN Code: 7228

Certification supplied: EN 10204 3.1 / Mill Test Certificate

Third-party inspection: SGS / BV / TUV (on request)

GCC · Middle East · Africa · Europe · North & South America

What is D2 tool steel flat bar used for?

D2 flat bars are used for cold-work tooling such as punches, shear blades, blanking dies, and cutting tools.

What is the difference between H11 and H13 tool steel flat bars?

H13 offers better hot hardness and thermal fatigue resistance compared to H11, making it suitable for die casting dies.

Are tool steel flat bars supplied in hardened condition?

No. They are supplied in annealed condition for machining and later heat treated as per tool requirement.

Can tool steel flat bars withstand high temperatures?

Yes. H11 and H13 are designed specifically for high-temperature hot-work applications.

Do you provide test certificates with tool steel flat bars?

Yes. All supplies include EN 10204 3.1 Mill Test Certificates.

Do you export tool steel flat bars?

Yes. We regularly export to GCC, Africa, Europe, and the Americas.

Whether you require D2 flat bars for cutting tools, H11 for forging tools, or H13 for die casting dies, our team will assist with grade selection, pricing, and delivery timelines.

D2 flat bars are used for cold-work tooling such as punches, shear blades, blanking dies, and cutting tools. H13 offers better hot hardness and thermal fatigue resistance compared to H11, making it suitable for die casting dies. No. They are supplied in annealed condition for machining and later heat treated as per tool requirement. Yes. H11 and H13 are designed specifically for high-temperature hot-work applications. All supplies include EN 10204 3.1 Mill Test Certificates. We regularly export to GCC, Africa, Europe, and the Americas. What is D2 tool steel flat bar used for?

What is the difference between H11 and H13 tool steel flat bars?

Are tool steel flat bars supplied in hardened condition?

Can tool steel flat bars withstand high temperatures?

Do you provide test certificates with tool steel flat bars?

Do you export tool steel flat bars?

WhatsApp us